- SAP Community

- Products and Technology

- Enterprise Resource Planning

- ERP Blogs by Members

- Concept of Discontinuation Data - Material Master ...

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

What do you mean by Discontinued Materials?

If you want to use some of the components in place of the original components and these original components are no more required, then in material master once you enter discontinued material which will prompt to give effective out date. That means from that date onwards substitute material is going to be used.

What data to be maintained for Discontinued Material?

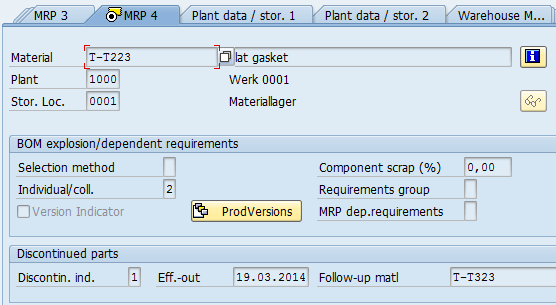

Material Master - MRP 4View

Discontinuation indicator - Identifies the material as a part to be discontinued and includes it in the discontinued parts procedure in materials planning.If this indicator is set, the system transfers the dependent requirements in materials planning to the follow-up material if they are no longer covered by warehouse stocks

There are two types of discontinuation which are Simple discontinuation and Dependent parallel discontinuation.

Simple discontinuation : A component to be discontinued is replaced with a follow-up component at a particular date. In the material master record of the component to be discontinued, you must set discontinuation indicator 1, enter a follow-up component, and specify an effective-out date.

Dependent parallel discontinuation: A group of materials is replaced with a group of materials; that is, if one component is to be discontinued (the main component), another component must also be discontinued (the subordinate component). In the material master record of the main component to be discontinued, you must set discontinuation indicator 1, enter a follow-up component, and specify an effective-out date. In the material master record of the subordinate component, you must set discontinuation indicator 3.

Follow-Up Material: Number of the material that the system uses in materials planning to replace the material to be discontinued once its warehouse stock is depleted. In the material master record and also in the bill of material (BOM), you can define a follow-up material for a material to be discontinued. The follow-up material defined in the BOM has a higher priority than that in the material master record.

Conditions for Discontinue Materials:

- The part to be discontinued and the follow-up material to be planned using material requirements planning (MRP)

- The base unit of measure of the follow-up material to be the same as that of the part to be discontinued

- In BOM, discontinuation data is maintained for the discontinued item and follow-up data is maintained for the follow-up item

- Item category should be stock item or variable size item.

Master data Maintained:

Step 1: Change Material Master( MM02)

In Material Master MRP 4 view for the discontinue material maintain the Discontin. ind = 1 , with Efft out date and follow-up material.

For the given example T-T223 is the discontinue material and T-T323 is the follow-up material. Settings are made as displayed below.

Step 2: Change BOM( CS02)

Follow up material to be included in BOM. T-T223 is discontiue material and T-T323 is follow up material

For discontinue material T-T23, Select the Discontinuation ind. as 1 and maintain the Discont.group as 01

Similarly for the Follow up material T-T323 maintain the Follow up group as 01.

Scenario 1: Master data maintained as explained above and stock of discontinue material is available. What will be the effect of discontinue material and follow-up material during MRP and Order creation.

Step 1: Stock Requirements List (MD04)

Currently there is stock of 40 qty available for the discontinue material (T-T223) as displayed below. Effective date is maintained as 19.03.2014.

Stock available for Follow-up material is 400 as displayed below.

Step 2 : PIR for FERT Material for 500 qty and MRP MD02 executed. Planned order created for 500 qty.

When replacing a component with another the stock of the discontinue material should be used up before the follow up material is introduced in order to avoid dead stock. During the planning run, the system checks the discontinuation indicator and the effective-out date in the material master and reassigns the materials correspondingly. The system reassigns the requirements during the planning run for the discontinued material.

Below screen shot displays the FERT planned order Component overview. Here we can see the discontinue material T-T223 available stock qty of 50 is considered and remaning qty 450 is considered from the follow up material T-T323.

As shown below for the discontinue material T-T223 MRP did not generate any procurement proposals since it is discontinue material with effective date 19.03.2014. Instead it created dependent requirement for 50 available qty. Once all the stocks of this material have been used up, its dependent equirements are reassigned to the follow-up material.

As shown below for the follow up material T-T323 MRP generated purchase requsition for 50 qty since 400 is already available against total dependent requirement of 450 qty.

Once Order is created for the FERT material acordingly reservations are generated for 50 qty for discontinue material(since stock available for 50 qty) and 450 qty for the follow up material.

In Nutshell, MRP will not generate procurement proposals from effective date for discontinue materials. Reservations will be generated for availale stock qty till stock of discontinue materials becomes zero and thereafter all the dependent requirements of discontinue materials be reassigned to follow up materials.

Note 1: If stock of the discontinue material is zero then when order is created for the parent material - in order componenet overview for discontinue material requirement qty will be displayed as ZERO and for folllow up material actual requirement qty will be displayed.

Note 2: If dicontinue data is maintained in Material Master and not maintained in BOM, MRP will not plan but in order, requirement qty will be displayed in order componenet overview as per BOM qty for both discontinue material and follow up material.

Note 3: If you try to set the discontinuation for a follow-up material, then error message "Message no. 61224 -Multi Level Discontinuation not suported" will be generated when you try to run MRP. Refer Note 398238 - Error message 61224 for parts provided

Reference :

Discontinuation - BOMs (PP-BD-BOM) - SAP Library

- SAP Managed Tags:

- MAN Production Planning (PP),

- MM (Materials Management)

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

-

"mm02"

1 -

A_PurchaseOrderItem additional fields

1 -

ABAP

1 -

ABAP Extensibility

1 -

ACCOSTRATE

1 -

ACDOCP

1 -

Adding your country in SPRO - Project Administration

1 -

Advance Return Management

1 -

AI and RPA in SAP Upgrades

1 -

Approval Workflows

1 -

ARM

1 -

ASN

1 -

Asset Management

1 -

Associations in CDS Views

1 -

auditlog

1 -

Authorization

1 -

Availability date

1 -

Azure Center for SAP Solutions

1 -

AzureSentinel

2 -

Bank

1 -

BAPI_SALESORDER_CREATEFROMDAT2

1 -

BRF+

1 -

BRFPLUS

1 -

Bundled Cloud Services

1 -

business participation

1 -

Business Processes

1 -

CAPM

1 -

Carbon

1 -

Cental Finance

1 -

CFIN

1 -

CFIN Document Splitting

1 -

Cloud ALM

1 -

Cloud Integration

1 -

condition contract management

1 -

Connection - The default connection string cannot be used.

1 -

Custom Table Creation

1 -

Customer Screen in Production Order

1 -

Data Quality Management

1 -

Date required

1 -

Decisions

1 -

desafios4hana

1 -

Developing with SAP Integration Suite

1 -

Direct Outbound Delivery

1 -

DMOVE2S4

1 -

EAM

1 -

EDI

2 -

EDI 850

1 -

EDI 856

1 -

EHS Product Structure

1 -

Emergency Access Management

1 -

Energy

1 -

EPC

1 -

Find

1 -

FINSSKF

1 -

Fiori

1 -

Flexible Workflow

1 -

Gas

1 -

Gen AI enabled SAP Upgrades

1 -

General

1 -

generate_xlsx_file

1 -

Getting Started

1 -

HomogeneousDMO

1 -

IDOC

2 -

Integration

1 -

Learning Content

2 -

LogicApps

2 -

low touchproject

1 -

Maintenance

1 -

management

1 -

Material creation

1 -

Material Management

1 -

MD04

1 -

MD61

1 -

methodology

1 -

Microsoft

2 -

MicrosoftSentinel

2 -

Migration

1 -

MRP

1 -

MS Teams

2 -

MT940

1 -

Newcomer

1 -

Notifications

1 -

Oil

1 -

open connectors

1 -

Order Change Log

1 -

ORDERS

2 -

OSS Note 390635

1 -

outbound delivery

1 -

outsourcing

1 -

PCE

1 -

Permit to Work

1 -

PIR Consumption Mode

1 -

PIR's

1 -

PIRs

1 -

PIRs Consumption

1 -

PIRs Reduction

1 -

Plan Independent Requirement

1 -

Premium Plus

1 -

pricing

1 -

Primavera P6

1 -

Process Excellence

1 -

Process Management

1 -

Process Order Change Log

1 -

Process purchase requisitions

1 -

Product Information

1 -

Production Order Change Log

1 -

Purchase requisition

1 -

Purchasing Lead Time

1 -

Redwood for SAP Job execution Setup

1 -

RISE with SAP

1 -

RisewithSAP

1 -

Rizing

1 -

S4 Cost Center Planning

1 -

S4 HANA

1 -

S4HANA

3 -

Sales and Distribution

1 -

Sales Commission

1 -

sales order

1 -

SAP

2 -

SAP Best Practices

1 -

SAP Build

1 -

SAP Build apps

1 -

SAP Cloud ALM

1 -

SAP Data Quality Management

1 -

SAP Maintenance resource scheduling

2 -

SAP Note 390635

1 -

SAP S4HANA

2 -

SAP S4HANA Cloud private edition

1 -

SAP Upgrade Automation

1 -

SAP WCM

1 -

SAP Work Clearance Management

1 -

Schedule Agreement

1 -

SDM

1 -

security

2 -

Settlement Management

1 -

soar

2 -

SSIS

1 -

SU01

1 -

SUM2.0SP17

1 -

SUMDMO

1 -

Teams

2 -

User Administration

1 -

User Participation

1 -

Utilities

1 -

va01

1 -

vendor

1 -

vl01n

1 -

vl02n

1 -

WCM

1 -

X12 850

1 -

xlsx_file_abap

1 -

YTD|MTD|QTD in CDs views using Date Function

1

- « Previous

- Next »

- Quick Start guide for PLM system integration 3.0 Implementation/Installation in Enterprise Resource Planning Blogs by SAP

- Introducing the market standard of electronic invoicing for the United States in Enterprise Resource Planning Blogs by SAP

- Purpose of valuation class in Enterprise Resource Planning Q&A

- Insights on Columnar store for SAP Functional Consultants in Enterprise Resource Planning Blogs by Members

- Deletion of Master and Transactional Data (ILM) in SAP S/4HANA Cloud,Public Edition-Link Collection in Enterprise Resource Planning Blogs by SAP

| User | Count |

|---|---|

| 2 | |

| 2 | |

| 2 | |

| 2 | |

| 2 | |

| 2 | |

| 2 | |

| 1 | |

| 1 | |

| 1 |