- SAP Community

- Products and Technology

- Enterprise Resource Planning

- ERP Blogs by Members

- Template Allocations. Other alternative to post Ac...

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

Hi Friends! I was looking for a topic that no much info is post on the internet and found interesting write about Template Allocation.

Im going to share a example of what you can do with Templates. The topic is huge and you can find lot info in SAP Help or in the ABC Costing academy course... this is just an appetizer, in order to kwow a bit of this functionality.

The basic:

There are lots ways to post a activity to a receiver (I guess you understand the concept of a sender and a receiver, and also know what is an activity type and how to plan), Examples are PP/PM/PS Notifications, KB21N from CO, CATS (I love cats!), indirect activity allocations or with bapi BAPI_ACC_ACTIVITY_ALLOC_POST.

Imaginary scenario:

PP Work Center have a max of 6 activities to post. Lot of companies say this is to few (well in PM/PS system thees only have 1, i dont understand why, but this is not our topic). Imagine you want to post aditional activities at PeriodEndClosing. Imagine your key user want to post 2 activities, 1 based on the ActualScrap of the PP Order and other based in a activity PP Boys post to the order with CO11N (yep, 6 are not enough).

If you analize carefully all the options i mention, non of them can accomplish the desired behavior (Well the ZBAPI can do whatever).

*** PS. the indirect activity allocation cant face the requirement of post based in actual activity posted on the PP Order. If you want to validate, go on!

The Customizing

1. I create a Template (tcode CPT2), that have 2 records>

KeyConcepts>

- Type: Represent what the row of the template is going to do. In my example, post activity from cost center.

- Object: Refer to the type, in this case the Sender CostCenter/Activity Type. In this example, is static but we can change it dynamically.

- Actual Quantity: the way the template calculate the actual QTY we will post to the reciever object, in our scenario a PP Order.

+ The 1st line post from the cost center 6000_PP001 with the activity PP0001 (Column Object) to the Reciever Order Based on the actual scrap posted

In order to do that, i use the standard method "OrderHeaderScrapQtyConfirm" that calculate the value. No abap code needed for this. This TemplateFunction do all the hard work!!

+ The 2nd line post from the cost center 6000_PP001 with the activity PP0002 to the Reciever Order, based on the actual quantity of the activity type 'PP0000' previosly posted to the PP Order (PP boys post this activvity wth CO11N) , activity 'PP0000' was posted from cost center "6000_PP001".

In order to do this, i create a template function "ZAllocatedActualQtyOrder01" as a copy of standard TemplateFunction "AllocatedActualQtyObjects" and did few changes (2 aditional variables, and 1 line of code). I did because the standard Function dont accomplish exactly what i want. The message here is I spend less than 10 minutes modifying the function, OK i know the function and also i did by my self so i dont need to tell a abap, give a specification and all the typical stuff necesary for a requirement but this is 1000 times easier and faster than create a ztcode from the scratch).

You specify the parameters that enter to the function. In this case, i set HardCode the Activity Type, but the cost center is a parameter {SenderCostCenter} and as you can imagine refer to the cost center in the column {Object} of the template, in our case "6000_PP001"

2. Create all the overhead stuff and assign to the PP Order. In tcode KTPF assing the Template to the Controlling Area / CostingSheet/Overhead Key/Enviroment. This is the only difference with the classical Overhead customizing .

* there are lot of info of overhead on the internet, so im not going to explain this custo.

The Master Data (No details, there are lot of info about this on the internet)

+ Create Activity, CostElements for activity Posting, Plan the activity in the cost center, and more...

+ Create a New Material FERT. Assing a OverheadGroup. This is our link to the template.

+ Create a WorkCenter

+ Create BOM, Routing,

+ Create PP Order, Post Activity and Scrap.

The Template in action:

1. Check the PP Order. You can see the actual activity qty PP0000 is 10.

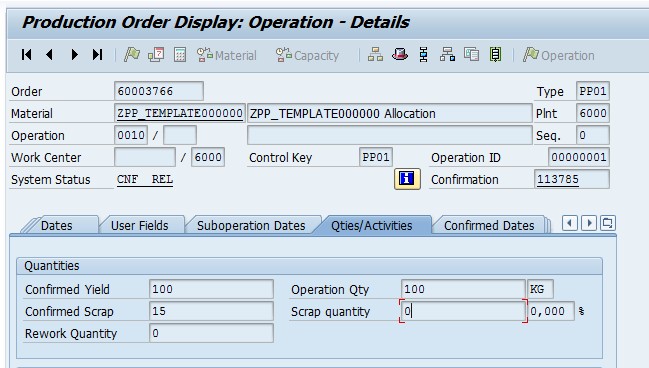

2. Also In the next screen you can see the actual Scrap "15" posted to the PP Order.

I run the Template Allocation Posting (tcode CPTA )

System post activity pp0001 with qty = 15 = The confirmed scrap in the pp order and pp0002 with qty = 10 = the actual post of activity pp0000.

Now you check the PP Order Cost and find the activity pp0001 and PP0002 posted with the template

What do you think?

The template use TemplateFunctions, assigned to a ABAP function. You can copy and modify the standard functions. In tcode CTU6 you can see all the available standard functions.

PS. I spend about 4hours doing the custo and creating the master data from the scratch, taking the screenshots and writing here .. Copy a standard funcion minimize the abap effort.

Arturo.

- SAP Managed Tags:

- FIN Controlling

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

-

"mm02"

1 -

A_PurchaseOrderItem additional fields

1 -

ABAP

1 -

ABAP Extensibility

1 -

ACCOSTRATE

1 -

ACDOCP

1 -

Adding your country in SPRO - Project Administration

1 -

Advance Return Management

1 -

AI and RPA in SAP Upgrades

1 -

Approval Workflows

1 -

ARM

1 -

ASN

1 -

Asset Management

1 -

Associations in CDS Views

1 -

auditlog

1 -

Authorization

1 -

Availability date

1 -

Azure Center for SAP Solutions

1 -

AzureSentinel

2 -

Bank

1 -

BAPI_SALESORDER_CREATEFROMDAT2

1 -

BRF+

1 -

BRFPLUS

1 -

Bundled Cloud Services

1 -

business participation

1 -

Business Processes

1 -

CAPM

1 -

Carbon

1 -

Cental Finance

1 -

CFIN

1 -

CFIN Document Splitting

1 -

Cloud ALM

1 -

Cloud Integration

1 -

condition contract management

1 -

Connection - The default connection string cannot be used.

1 -

Custom Table Creation

1 -

Customer Screen in Production Order

1 -

Data Quality Management

1 -

Date required

1 -

Decisions

1 -

desafios4hana

1 -

Developing with SAP Integration Suite

1 -

Direct Outbound Delivery

1 -

DMOVE2S4

1 -

EAM

1 -

EDI

2 -

EDI 850

1 -

EDI 856

1 -

edocument

1 -

EHS Product Structure

1 -

Emergency Access Management

1 -

Energy

1 -

EPC

1 -

Financial Operations

1 -

Find

1 -

FINSSKF

1 -

Fiori

1 -

Flexible Workflow

1 -

Gas

1 -

Gen AI enabled SAP Upgrades

1 -

General

1 -

generate_xlsx_file

1 -

Getting Started

1 -

HomogeneousDMO

1 -

IDOC

2 -

Integration

1 -

Learning Content

2 -

LogicApps

2 -

low touchproject

1 -

Maintenance

1 -

management

1 -

Material creation

1 -

Material Management

1 -

MD04

1 -

MD61

1 -

methodology

1 -

Microsoft

2 -

MicrosoftSentinel

2 -

Migration

1 -

MRP

1 -

MS Teams

2 -

MT940

1 -

Newcomer

1 -

Notifications

1 -

Oil

1 -

open connectors

1 -

Order Change Log

1 -

ORDERS

2 -

OSS Note 390635

1 -

outbound delivery

1 -

outsourcing

1 -

PCE

1 -

Permit to Work

1 -

PIR Consumption Mode

1 -

PIR's

1 -

PIRs

1 -

PIRs Consumption

1 -

PIRs Reduction

1 -

Plan Independent Requirement

1 -

Premium Plus

1 -

pricing

1 -

Primavera P6

1 -

Process Excellence

1 -

Process Management

1 -

Process Order Change Log

1 -

Process purchase requisitions

1 -

Product Information

1 -

Production Order Change Log

1 -

Purchase requisition

1 -

Purchasing Lead Time

1 -

Redwood for SAP Job execution Setup

1 -

RISE with SAP

1 -

RisewithSAP

1 -

Rizing

1 -

S4 Cost Center Planning

1 -

S4 HANA

1 -

S4HANA

3 -

Sales and Distribution

1 -

Sales Commission

1 -

sales order

1 -

SAP

2 -

SAP Best Practices

1 -

SAP Build

1 -

SAP Build apps

1 -

SAP Cloud ALM

1 -

SAP Data Quality Management

1 -

SAP Maintenance resource scheduling

2 -

SAP Note 390635

1 -

SAP S4HANA

2 -

SAP S4HANA Cloud private edition

1 -

SAP Upgrade Automation

1 -

SAP WCM

1 -

SAP Work Clearance Management

1 -

Schedule Agreement

1 -

SDM

1 -

security

2 -

Settlement Management

1 -

soar

2 -

SSIS

1 -

SU01

1 -

SUM2.0SP17

1 -

SUMDMO

1 -

Teams

2 -

User Administration

1 -

User Participation

1 -

Utilities

1 -

va01

1 -

vendor

1 -

vl01n

1 -

vl02n

1 -

WCM

1 -

X12 850

1 -

xlsx_file_abap

1 -

YTD|MTD|QTD in CDs views using Date Function

1

- « Previous

- Next »

- Enterprise Portfolio and Project Management in SAP S/4HANA Cloud, Private Edition 2023 FPS1 in Enterprise Resource Planning Blogs by SAP

- Direct Activity Allocation in decimals in Enterprise Resource Planning Q&A

- Lean Service Enablement for Project Networks in Enterprise Resource Planning Blogs by SAP

- Readiness for Universal Parallel Accounting in Enterprise Resource Planning Blogs by SAP

- Continuous Influence Session SAP S/4HANA Cloud, private edition: Results Review Cycle for Q4 2023 in Enterprise Resource Planning Blogs by SAP

| User | Count |

|---|---|

| 6 | |

| 2 | |

| 2 | |

| 2 | |

| 2 | |

| 2 | |

| 1 | |

| 1 | |

| 1 |