- SAP Community

- Products and Technology

- Enterprise Resource Planning

- ERP Blogs by Members

- Usage of Revision Level for PP Masters -BOM and Ro...

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

This Blog details the usage of revision levels for creation and change of PP masters like BOM and Routing. It gives an insight on how master data is tracked with different revision levels.

Requirement:

In a public sector client, there was requirement to map the drawing number and its alteration index in SAP PP process. Design department who owns the ownership for product designs creates design drawing and sends to planning department with some alteration index like 'a' or 'A' etc. Planning department identifies, defines structure, executes product manuafcturing based on the drawing and its aleration index. Even quality department tracks the inspection with respective to drawing number and its alternation index. Another challenge is there will be changes for the intial design where in the alteration index will be changed from 'a' to 'b' or 'b' to 'c' etc. This change can happen during planning or while executing the production.Finally at the end of the day, report is required to see the history of changes.

Approach used:

Engineering Change Management(ECM) is used to track and control all the changes with reference to Material master, BOM, Work Center & Routing. Mapped drawing number as material number and alteration index as revision level.

Configuration Used:

ECM Control Data ( OS54)

Change Master Number Ranges (OS53)

Standard config used.

Define Revision Levels (OS55) - Revision levels defined as required.

Define Modification Parameters for BOM (OS27)

Profile PP000001:

OP5A: PP task lists: initial screen -> Change number -> Transaction code -> Tick Req

While creating the routing revision level field should be mandatory. Below is the config

Steps followed for creating and changing the master data:

- Create change number(CC01)

- Assign change number to Material (CC11) with initial revision level

- Create BOM (CS01) and Routing (CA01) with revision level

- Create new change number with different validity date (CC01) and assign to material with new revision level (CC11)

- Display revision levels (CC12)

- Change BOM(CS02) and Routing with new revision level (CA02)

Step 1: Create change number( Tcode CC01) - Select the profile created PP000001 as displayed below. Maintain the change number description, valid from date. On save change number gets created.

Step 2: Assign Revision level to Material (CC11) - Against the material change number and revision is entered.

Before assigning the revision level in MM02 for the material M-800 there is no revision level as displayed below

Go to CC11, enter material number, change number and select the revision level A and enter. System will copy the valid date of the revision level A. Then SAVE.

If we now go to MM03 and check revision level gets assigned to materia las given below

Step 3: Create BOM with respect to revision level - CS01

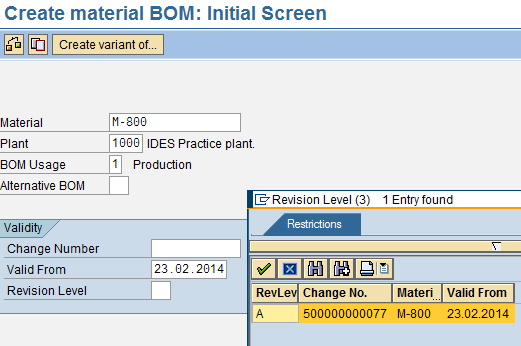

Enter material number, plant, BOM usage as 1 and put F4 on revision level. System will display the available revision level and its change number as displayed below. In order to make the Revision level field as mandatory used transaction variant for CS01/CS02.

Select the change revision level A. System will copy the change number and valid from date as displayed below.

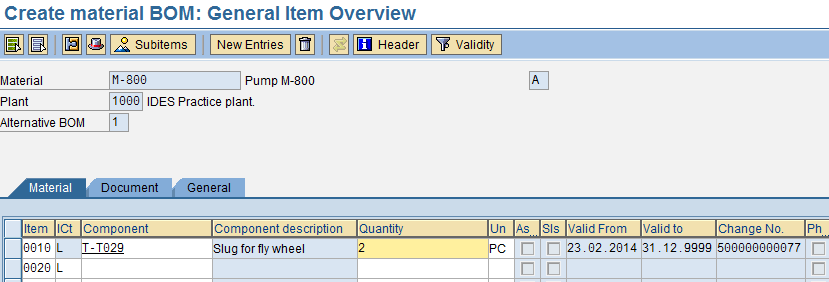

Once we click enter system displays BOM general item overview screen. Maintain the BOM materials. Component T-T029 maintained with qty as 2 pc as given below. Revision level will be displayed besides the Material number and change number displayed towards right of the BOM items. Now the present BOM is valid for revision level A only.

Step 4: Create Routing with respect to revision level - CA01

Enter Material number, Plant and Put F4 on revision level. Based on config set in OP5A revision level is mandatory as displayed below.

Revision level and change number along with valid date is copied as displayed below.

On enter routing operation screen is displaed where operations are maintained as displayed below.

In BOM only one component is available and is assigned to operation 0010 as displayed below.

As displayed below routing is created against the revision level A and its change number can be seen below.

Step 5 : Changes to Master Data with revision level B (BOM and Routing):

New change number 500000000078 created with valid date as 24.02.2014 for change in revision level from A to B. Revision level B assigned in CC11. After assigning in material master new revision level B will be displayed as given below.

System now displays both revision levels in CC12 as displayed below.

BOM: BOM is now to be changed with revision level B. In CS02 under revision level two revision levels A and B will be displayed. Latest is the new revision level given for the material.

With revision level B BOM is changed as below.Item 0010 component qty chnaged from 2 to 4 pc and new bom item 0020 added. Here we can see the new revision level B for the

header material displayed besides material number.

Routing: Similarly routing changed with new revision level B as displayed below.

In Revision level B, material number T-T029 is re-assigned to operation 0020 and new material which was added in BOM was assigned to operation 0010.

Transaction Data:

Created production order, system picked revision level A for the Master data. In order BOM as per revision level A only one BOM item is available and displayed below.

When we use Read Master data( Case -Only order is relased no other movement are done) there will be option to select the revision level as displayed below. Revision level B selected. Now BOM and Routing of revision level B will get copied on order.

Now Order BOM shows two BOM items as per new revision level B

BOM items are also accordingly assigned to the respective oprations as per revision level B as displayed below.

Reports:

CS11 : Report displayed based on revision level.

Revision level A report with only one BOM material

Revision level B report with two BOM materials.

Difference between revision level A and B. When we go to tcode CS14 BOM comparision then difference between the revision levels is displayed as given below.

Conclusion:

- Changes to the BOM and Routing are tracked perfectly through revision level provided revision level field is made mandatory in both BOM and Routing.

- Based on the latest revision level and validity date master like BOM and Routings gets copied to order.

- BOM materials which are added with new revision level will be greyed out incase trying to change the BOM with older revision level

- Order information data(COOIS) will be displayed with historical revision level data for the respective orders.

- SAP Managed Tags:

- MAN Production Planning (PP),

- MM (Materials Management)

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

-

"mm02"

1 -

A_PurchaseOrderItem additional fields

1 -

ABAP

1 -

ABAP Extensibility

1 -

ACCOSTRATE

1 -

ACDOCP

1 -

Adding your country in SPRO - Project Administration

1 -

Advance Return Management

1 -

AI and RPA in SAP Upgrades

1 -

Approval Workflows

1 -

ARM

1 -

ASN

1 -

Asset Management

1 -

Associations in CDS Views

1 -

auditlog

1 -

Authorization

1 -

Availability date

1 -

Azure Center for SAP Solutions

1 -

AzureSentinel

2 -

Bank

1 -

BAPI_SALESORDER_CREATEFROMDAT2

1 -

BRF+

1 -

BRFPLUS

1 -

Bundled Cloud Services

1 -

business participation

1 -

Business Processes

1 -

CAPM

1 -

Carbon

1 -

Cental Finance

1 -

CFIN

1 -

CFIN Document Splitting

1 -

Cloud ALM

1 -

Cloud Integration

1 -

condition contract management

1 -

Connection - The default connection string cannot be used.

1 -

Custom Table Creation

1 -

Customer Screen in Production Order

1 -

Data Quality Management

1 -

Date required

1 -

Decisions

1 -

desafios4hana

1 -

Developing with SAP Integration Suite

1 -

Direct Outbound Delivery

1 -

DMOVE2S4

1 -

EAM

1 -

EDI

2 -

EDI 850

1 -

EDI 856

1 -

edocument

1 -

EHS Product Structure

1 -

Emergency Access Management

1 -

Energy

1 -

EPC

1 -

Financial Operations

1 -

Find

1 -

FINSSKF

1 -

Fiori

1 -

Flexible Workflow

1 -

Gas

1 -

Gen AI enabled SAP Upgrades

1 -

General

1 -

generate_xlsx_file

1 -

Getting Started

1 -

HomogeneousDMO

1 -

IDOC

2 -

Integration

1 -

Learning Content

2 -

LogicApps

2 -

low touchproject

1 -

Maintenance

1 -

management

1 -

Material creation

1 -

Material Management

1 -

MD04

1 -

MD61

1 -

methodology

1 -

Microsoft

2 -

MicrosoftSentinel

2 -

Migration

1 -

MRP

1 -

MS Teams

2 -

MT940

1 -

Newcomer

1 -

Notifications

1 -

Oil

1 -

open connectors

1 -

Order Change Log

1 -

ORDERS

2 -

OSS Note 390635

1 -

outbound delivery

1 -

outsourcing

1 -

PCE

1 -

Permit to Work

1 -

PIR Consumption Mode

1 -

PIR's

1 -

PIRs

1 -

PIRs Consumption

1 -

PIRs Reduction

1 -

Plan Independent Requirement

1 -

Premium Plus

1 -

pricing

1 -

Primavera P6

1 -

Process Excellence

1 -

Process Management

1 -

Process Order Change Log

1 -

Process purchase requisitions

1 -

Product Information

1 -

Production Order Change Log

1 -

Purchase requisition

1 -

Purchasing Lead Time

1 -

Redwood for SAP Job execution Setup

1 -

RISE with SAP

1 -

RisewithSAP

1 -

Rizing

1 -

S4 Cost Center Planning

1 -

S4 HANA

1 -

S4HANA

3 -

Sales and Distribution

1 -

Sales Commission

1 -

sales order

1 -

SAP

2 -

SAP Best Practices

1 -

SAP Build

1 -

SAP Build apps

1 -

SAP Cloud ALM

1 -

SAP Data Quality Management

1 -

SAP Maintenance resource scheduling

2 -

SAP Note 390635

1 -

SAP S4HANA

2 -

SAP S4HANA Cloud private edition

1 -

SAP Upgrade Automation

1 -

SAP WCM

1 -

SAP Work Clearance Management

1 -

Schedule Agreement

1 -

SDM

1 -

security

2 -

Settlement Management

1 -

soar

2 -

SSIS

1 -

SU01

1 -

SUM2.0SP17

1 -

SUMDMO

1 -

Teams

2 -

User Administration

1 -

User Participation

1 -

Utilities

1 -

va01

1 -

vendor

1 -

vl01n

1 -

vl02n

1 -

WCM

1 -

X12 850

1 -

xlsx_file_abap

1 -

YTD|MTD|QTD in CDs views using Date Function

1

- « Previous

- Next »

- Quick Start guide for PLM system integration 3.0 Implementation/Installation in Enterprise Resource Planning Blogs by SAP

- SAP S/4HANA Cloud Private Edition | 2023 FPS01 Release – Part 1 in Enterprise Resource Planning Blogs by SAP

- Production / Process Order Change Log using SAP Note: 390635 in Enterprise Resource Planning Blogs by Members

- Comibined Master Recipe and Routing to produce a single Work order in Enterprise Resource Planning Q&A

- Utilize Change Master in Manage Routing App in Enterprise Resource Planning Q&A

| User | Count |

|---|---|

| 6 | |

| 2 | |

| 2 | |

| 2 | |

| 2 | |

| 2 | |

| 2 | |

| 1 | |

| 1 |