- SAP Community

- Products and Technology

- Enterprise Resource Planning

- ERP Blogs by Members

- Is it possible to PGI when delivery and picking qu...

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

Hi,

I've updated this document adding an example run in WM and added business case scenarios where this solution should be implemented and cases where quantity difference could happen.

Is it possible to PGI when delivery and picking quantities are different? In many forums i've seen answers that this is not possible.

However, it is possible when the picking quantity is greater than delivery quantity (over picking). Do you want to know how? Keep reading!

Before changes

After

Let’s go:

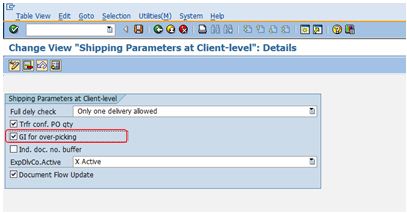

Customizing, logistics, shipping, Configure Global Shipping Data

Tick on entry GI for over picking

Now, run OVM1 to customize error messages VL 019 from E (error) to W (warning)

That’s all.

When posting goods issue, if delivery quantity differs from picking quantity, which is the case, posted quantity is that of delivery quantity.

Once billed document, flow for line item displays it as completed

Let’s see what happens when working with WM.

We can create a TO with different picking quantity and confirm this quantity when confirming TO. When doing PGI, differences between delivery quantity and picking quantity remain in storage location 916 and have to be removed.

What’s the business case?

I found different business case to use this setting in the system:

- Avoid issues when running PGI automated processes due to differences between quantities in delivery and picking (over delivery).

- Solve error VL 632 in WM. Rounding differences may happen if sales unit measure in master material is smaller than the base unit of measure: in delivery, the quantities in base unit of measure are calculated internally with 3 decimals (further details in OSS note 1621474).

- Overpass incompleteness procedure for delivery item if used field V50UC-OVPIK (picking qty > qty to be delivered) as a result of rounding differences (OSS note 707208).

In which cases could we have different quantities?

- I could happen due to manual mistakes when typing picked quantities in warehouse or when receiving picked quantities by IDOC, barcode scanning, a malfunctioning of an interface... as shown in examples in this document.

- if sales unit measure in master material is smaller than the base unit of measure: in delivery, the quantities in base unit of measure are calculated internally with 3 decimals leading to differences because of rounding.

Regards,

JM

- SAP Managed Tags:

- SD (Sales and Distribution)

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

-

"mm02"

1 -

A_PurchaseOrderItem additional fields

1 -

ABAP

1 -

ABAP Extensibility

1 -

ACCOSTRATE

1 -

ACDOCP

1 -

Adding your country in SPRO - Project Administration

1 -

Advance Return Management

1 -

AI and RPA in SAP Upgrades

1 -

Approval Workflows

1 -

ARM

1 -

ASN

1 -

Asset Management

1 -

Associations in CDS Views

1 -

auditlog

1 -

Authorization

1 -

Availability date

1 -

Azure Center for SAP Solutions

1 -

AzureSentinel

2 -

Bank

1 -

BAPI_SALESORDER_CREATEFROMDAT2

1 -

BRF+

1 -

BRFPLUS

1 -

Bundled Cloud Services

1 -

business participation

1 -

Business Processes

1 -

CAPM

1 -

Carbon

1 -

Cental Finance

1 -

CFIN

1 -

CFIN Document Splitting

1 -

Cloud ALM

1 -

Cloud Integration

1 -

condition contract management

1 -

Connection - The default connection string cannot be used.

1 -

Custom Table Creation

1 -

Customer Screen in Production Order

1 -

Data Quality Management

1 -

Date required

1 -

Decisions

1 -

desafios4hana

1 -

Developing with SAP Integration Suite

1 -

Direct Outbound Delivery

1 -

DMOVE2S4

1 -

EAM

1 -

EDI

2 -

EDI 850

1 -

EDI 856

1 -

edocument

1 -

EHS Product Structure

1 -

Emergency Access Management

1 -

Energy

1 -

EPC

1 -

Financial Operations

1 -

Find

1 -

FINSSKF

1 -

Fiori

1 -

Flexible Workflow

1 -

Gas

1 -

Gen AI enabled SAP Upgrades

1 -

General

1 -

generate_xlsx_file

1 -

Getting Started

1 -

HomogeneousDMO

1 -

IDOC

2 -

Integration

1 -

learning content

2 -

LogicApps

2 -

low touchproject

1 -

Maintenance

1 -

management

1 -

Material creation

1 -

Material Management

1 -

MD04

1 -

MD61

1 -

methodology

1 -

Microsoft

2 -

MicrosoftSentinel

2 -

Migration

1 -

MRP

1 -

MS Teams

2 -

MT940

1 -

Newcomer

1 -

Notifications

1 -

Oil

1 -

open connectors

1 -

Order Change Log

1 -

ORDERS

2 -

OSS Note 390635

1 -

outbound delivery

1 -

outsourcing

1 -

PCE

1 -

Permit to Work

1 -

PIR Consumption Mode

1 -

PIR's

1 -

PIRs

1 -

PIRs Consumption

1 -

PIRs Reduction

1 -

Plan Independent Requirement

1 -

Premium Plus

1 -

pricing

1 -

Primavera P6

1 -

Process Excellence

1 -

Process Management

1 -

Process Order Change Log

1 -

Process purchase requisitions

1 -

Product Information

1 -

Production Order Change Log

1 -

Purchase requisition

1 -

Purchasing Lead Time

1 -

Redwood for SAP Job execution Setup

1 -

RISE with SAP

1 -

RisewithSAP

1 -

Rizing

1 -

S4 Cost Center Planning

1 -

S4 HANA

1 -

S4HANA

3 -

Sales and Distribution

1 -

Sales Commission

1 -

sales order

1 -

SAP

2 -

SAP Best Practices

1 -

SAP Build

1 -

SAP Build apps

1 -

SAP Cloud ALM

1 -

SAP Data Quality Management

1 -

SAP Maintenance resource scheduling

2 -

SAP Note 390635

1 -

SAP S4HANA

2 -

SAP S4HANA Cloud private edition

1 -

SAP Upgrade Automation

1 -

SAP WCM

1 -

SAP Work Clearance Management

1 -

Schedule Agreement

1 -

SDM

1 -

security

2 -

Settlement Management

1 -

soar

2 -

SSIS

1 -

SU01

1 -

SUM2.0SP17

1 -

SUMDMO

1 -

Teams

2 -

User Administration

1 -

User Participation

1 -

Utilities

1 -

va01

1 -

vendor

1 -

vl01n

1 -

vl02n

1 -

WCM

1 -

X12 850

1 -

xlsx_file_abap

1 -

YTD|MTD|QTD in CDs views using Date Function

1

- « Previous

- Next »

- Change material cost in Sales return process during PGR in Enterprise Resource Planning Q&A

- How to generate quality certificates for outbound deliveries? in Enterprise Resource Planning Q&A

- Collective processing of PR's generated by MRP in S4 Hana Public Cloud in Enterprise Resource Planning Q&A

- Additional TO got created with over picked quantity in Enterprise Resource Planning Q&A

- Manage Supply Shortage and Excess Supply with MRP Material Coverage Apps in Enterprise Resource Planning Blogs by SAP

| User | Count |

|---|---|

| 2 | |

| 2 | |

| 2 | |

| 2 | |

| 2 | |

| 2 | |

| 2 | |

| 2 | |

| 1 | |

| 1 |