- SAP Community

- Products and Technology

- Enterprise Resource Planning

- ERP Blogs by Members

- Basics of SAP Standard Cost estimate- Understandin...

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

There is a lot of forum question answers and content available in SCN about Standard Costing

Note-This is a beginner's and basic guide to understand cost estimate and various settings behind it.

This document is intended to explain the cost flows to a standard cost estimate. Explaining various settings in background. I will try to explain this from backward from Cost estimate to configuration. This will answer some basic questions like Material Cost, Overhead Cost, Labor etc. in a standard cost.

When you take a look at a material cost estimate what you will understand the Quantity Structure, Valuation, Costing Dates etc.

- Standard cost of a material looks like in T-Code- CK13n (you can view this from costing-2 view in material master too T-Code-MM03.)

- I will try to walk through these 6 tabs below explaining basic configurations and data flows from different configuration to Standard Cost estimate.

Screenshot-1

- For our analysis purpose I have selected standard layout 1SAP02-Costing items (overview)

- there are several layout available in standard SAP and user can define their own too.

Screenshot-2

Screenshot-3

1-Costing Data-

It contains data like Costing variant, Costing Version, Lot Size and Transfer Control. Lets talk about Costing Messages and Costing status later on.

Screenshot -4

- Costing variant-Configuration Costing Variant in T-code OKKN- (Will cover in more detailed way in part 2.)

-Assign various Control parameters like Costing Type, Valuation variant, Date Control QTY structure Control, Transfer Control etc.

-Maintain parameters different Tabs like Control, Qty Structure, Addictive Cost, Assignment and Misc.

Screenshot 5

- Costing Version configuration using T CODE- OKYD

-Number that serves to differentiate between cost estimates for the same material.

Screenshot 6

- Lot Size

- The costing lot size in the material master record is usually used as a basis for costing all materials, however one can manually change the lot size during cost estimate.

- Transfer Control-Configure in T-code OKKM usually used the standard.

Screenshot 7

- This controls how costing with quantity structure searches for existing cost estimates when existing costing data are transferred to another cost estimate. In this example we assigned PC02 in TCODE OKKN.

2-Costing Dates-we will learn more about date control in Costing variant

Screenshot 8

-Costing Date from -Date from which the cost estimate is valid.

-Costing Date to- This date determines the date up to which the cost estimate is valid

-Qty Structure Date-Date with which the quantity structure is selected for the cost estimate with quantity structure.

-Valuation Date-Date on which the materials and activities in a cost estimate are valuated.

3-Qty Structure-It contains BOM and Routing data. ( Usually PP functionality)

Screenshot 9

- Bill Of Material (BOM)- T CODE- SET up CS01 , To view T-code -CS03

Screenshot 10

If you go back and refer my screenshot 3 the detailed cost (M) comes from this settings.

Note- we will have to do cost component settings too will cover the point in net part.

- Routings- Create Routings T-Cod-CA01 ( PP functionality) to view CA03

- A routing shows operations in a sequence. This form the basis for

Lead time scheduling. Product costing, capacity planning, Refer screenshot 3 Cost Internal Activity (E) comes from this settings. We will understand more detail in my next part about assigning work center, activity and activity planning.

Screenshot 11

4- Valuation- It contains the currency, Costing sheet and Overhead key.

T CODE-KZS2-Creating and maintaining Costing Sheet,

T CODE-KOOK-Defining and changing Overhead key

Screenshot 12

if you refer to screenshot 3 Overhead cost (G) flows from this settings from costing sheet and overhead key.

- Costing Sheet-It controls the calculation of Overhead basically we use one costing sheet for each object for which system is to determine overhead costs. ( will see more detail in my next part)

- The Overhead Key-The overhead key is used to determine order-specific or material-related overhead rates. The overhead amounts depend on the plant and the overhead key. The overhead depends primarily on the overhead key. If an overhead key is not maintained for the material or the order, overhead is to be determined in relation to the plant.

After defining a costing sheet that points to two condition tables. In the first table, the overhead amount depends on the overhead key. In the second table, the overhead amount depends on the plant. An access sequence determines which conditions have priority.

5- HISTORY- It contains the user and costing run date data.

Screenshot 13

Cost By/Marked By/released By- The user names who performed respective costing run task.

Some large companies have different person to mark the cost and different person to release the cost as it rectifies the human errors if any. But in my experience i have seen mostly it is performed by the same person.

Costing run - usually this data updated when we use T-code CK40n to do standard costing in case of individual material costing using CK11n this field will not populate. So we can always go and check that costing run data to verify the settings at that point of time.

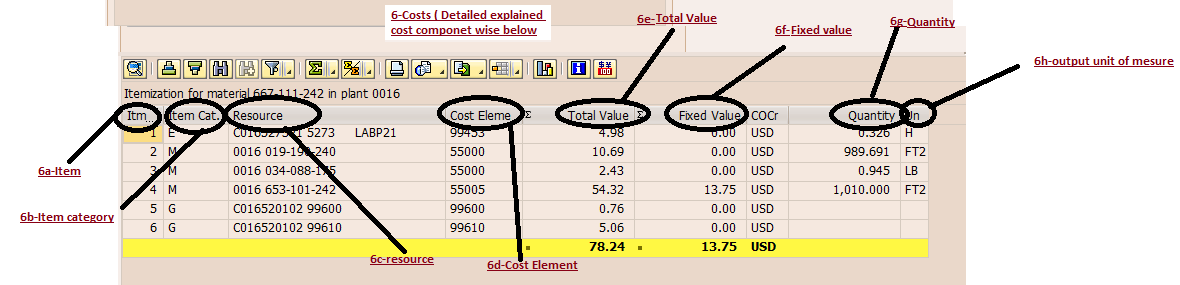

6-Costs-Baiscally it is summarization and cost component view

TCODE-OKTZ setting up cost component Structure (we will see in detail in part 2 of this document)

- If you refer back screenshot 8 breaking out cost like overhead, labor and material based on these settings here.In Product Cost Controlling, the cost component structure determines how the results of material costing are updated. The cost component structure groups the costs for each material according to cost component (such as material costs, internal activities, external activities, and overhead). If the material is used in the production of another material, the cost component split (which breaks down the costs according to material costs, internal activities, external activities, overhead, and so forth) remains in the system when the costs are rolled up

Screenshot 14

Error Log- Identifies the messages if costed with error or without error.

Intention of creating this document is to reach out to the beginners and those who wanted to know and understand the flow of Standard Costing. i will update the document as n when some more points needs to be included .

This is my first document and I should thank ajay.maheshwari Forum members,and SCN SAP ERP Financials - Controlling

I was nervous to put together the basics in a document and publish it in SCN. I will continue edit it for improvement.

The next part of document will update the more detailed configuration and steps to understand Basics of Standard costing

Refer to next part here http://scn.sap.com/docs/DOC-49167

Best Regards

Hrusikesh Dalai

- SAP Managed Tags:

- SAP ERP,

- FIN (Finance),

- FIN Controlling,

- MAN Production Planning (PP)

- accounting

- available

- beginner

- bp

- budget

- business process expert

- Center

- check

- co

- co-pa

- controlling

- copa

- copc

- cost

- costing

- costing variant

- costplanned

- costsstandart

- direct debit item

- enterprise resource planning

- enterprise support academy

- ERP

- erp financials

- es academy

- fico

- fico-beginers

- fico-ps

- Finance

- financials

- logistics

- management accounting

- mandate

- mapping

- material

- material ledger

- Material Management

- material planning

- materials management

- md04

- md05

- mm

- mrp

- mrp list

- order

- planned

- planned orders

- Planning

- plant

- po

- pp

- pp module

- product costing

- production

- Production order

- production scheduling

- purchasing

- Sales

- sales order

- SAP

- sap enterprise support academy

- sap erp financials

- sap erp manufacturing production planning

- SAP Finance And Controlling Accelerator

- sap sd

- sapmentor

- scn

- SD

- single euro payments area

- standard

- stock requirements list

- « Previous

-

- 1

- 2

- 3

- Next »

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

-

"mm02"

1 -

A_PurchaseOrderItem additional fields

1 -

ABAP

1 -

ABAP Extensibility

1 -

ACCOSTRATE

1 -

ACDOCP

1 -

Adding your country in SPRO - Project Administration

1 -

Advance Return Management

1 -

AI and RPA in SAP Upgrades

1 -

Approval Workflows

1 -

ARM

1 -

ASN

1 -

Asset Management

1 -

Associations in CDS Views

1 -

auditlog

1 -

Authorization

1 -

Availability date

1 -

Azure Center for SAP Solutions

1 -

AzureSentinel

2 -

Bank

1 -

BAPI_SALESORDER_CREATEFROMDAT2

1 -

BRF+

1 -

BRFPLUS

1 -

Bundled Cloud Services

1 -

business participation

1 -

Business Processes

1 -

CAPM

1 -

Carbon

1 -

Cental Finance

1 -

CFIN

1 -

CFIN Document Splitting

1 -

Cloud ALM

1 -

Cloud Integration

1 -

condition contract management

1 -

Connection - The default connection string cannot be used.

1 -

Custom Table Creation

1 -

Customer Screen in Production Order

1 -

Data Quality Management

1 -

Date required

1 -

Decisions

1 -

desafios4hana

1 -

Developing with SAP Integration Suite

1 -

Direct Outbound Delivery

1 -

DMOVE2S4

1 -

EAM

1 -

EDI

2 -

EDI 850

1 -

EDI 856

1 -

EHS Product Structure

1 -

Emergency Access Management

1 -

Energy

1 -

EPC

1 -

Find

1 -

FINSSKF

1 -

Fiori

1 -

Flexible Workflow

1 -

Gas

1 -

Gen AI enabled SAP Upgrades

1 -

General

1 -

generate_xlsx_file

1 -

Getting Started

1 -

HomogeneousDMO

1 -

IDOC

2 -

Integration

1 -

Learning Content

2 -

LogicApps

2 -

low touchproject

1 -

Maintenance

1 -

management

1 -

Material creation

1 -

Material Management

1 -

MD04

1 -

MD61

1 -

methodology

1 -

Microsoft

2 -

MicrosoftSentinel

2 -

Migration

1 -

MRP

1 -

MS Teams

2 -

MT940

1 -

Newcomer

1 -

Notifications

1 -

Oil

1 -

open connectors

1 -

Order Change Log

1 -

ORDERS

2 -

OSS Note 390635

1 -

outbound delivery

1 -

outsourcing

1 -

PCE

1 -

Permit to Work

1 -

PIR Consumption Mode

1 -

PIR's

1 -

PIRs

1 -

PIRs Consumption

1 -

PIRs Reduction

1 -

Plan Independent Requirement

1 -

Premium Plus

1 -

pricing

1 -

Primavera P6

1 -

Process Excellence

1 -

Process Management

1 -

Process Order Change Log

1 -

Process purchase requisitions

1 -

Product Information

1 -

Production Order Change Log

1 -

Purchase requisition

1 -

Purchasing Lead Time

1 -

Redwood for SAP Job execution Setup

1 -

RISE with SAP

1 -

RisewithSAP

1 -

Rizing

1 -

S4 Cost Center Planning

1 -

S4 HANA

1 -

S4HANA

3 -

Sales and Distribution

1 -

Sales Commission

1 -

sales order

1 -

SAP

2 -

SAP Best Practices

1 -

SAP Build

1 -

SAP Build apps

1 -

SAP Cloud ALM

1 -

SAP Data Quality Management

1 -

SAP Maintenance resource scheduling

2 -

SAP Note 390635

1 -

SAP S4HANA

2 -

SAP S4HANA Cloud private edition

1 -

SAP Upgrade Automation

1 -

SAP WCM

1 -

SAP Work Clearance Management

1 -

Schedule Agreement

1 -

SDM

1 -

security

2 -

Settlement Management

1 -

soar

2 -

SSIS

1 -

SU01

1 -

SUM2.0SP17

1 -

SUMDMO

1 -

Teams

2 -

User Administration

1 -

User Participation

1 -

Utilities

1 -

va01

1 -

vendor

1 -

vl01n

1 -

vl02n

1 -

WCM

1 -

X12 850

1 -

xlsx_file_abap

1 -

YTD|MTD|QTD in CDs views using Date Function

1

- « Previous

- Next »

- What are the pre-requisite to get SAP B1 Partner for any company? in Enterprise Resource Planning Q&A

- VAKEY operation used in PCR to refers to custom ABAP code in Enterprise Resource Planning Q&A

- Cost in the Pricing tab when creating Customer Return wo reference in Enterprise Resource Planning Q&A

- Rebate Accruals validity period issue in Enterprise Resource Planning Q&A

- FAQ on Upgrading SAP S/4HANA Cloud Public Edition in Enterprise Resource Planning Blogs by SAP

| User | Count |

|---|---|

| 2 | |

| 2 | |

| 2 | |

| 2 | |

| 2 | |

| 1 | |

| 1 | |

| 1 | |

| 1 | |

| 1 |