- SAP Community

- Products and Technology

- Enterprise Resource Planning

- ERP Blogs by Members

- Service Management - Set Scheduling Parameters

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

This is the second piece of the Scheduling portion for Service Orders. To many of you, this might seem silly to even be writing about some of these pieces, but I've been surprised as how many companies really do no scheduling of their service orders, don't worry about service part scheduling or anything like that. It seems that only lately, are more and more companies realizing the value of service and that they should be including them as part of MRP. So that being said, I'm going to go over the scheduling parameters.

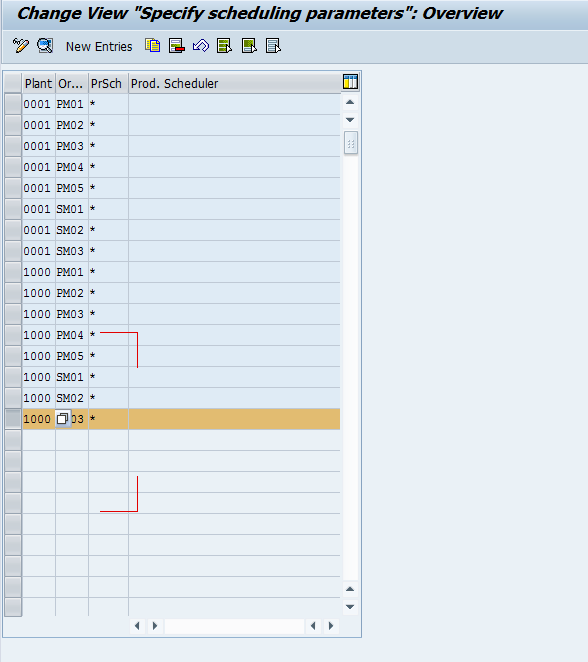

Here's reminder on where to locate this in configuration.

Next up you'll get a list of all the order types, and the plant. Notice, that you can even get more specific based on the production scheduler. If you don't feel like going to that level of detail, just use a * and every production scheduler will use the same settings.

Now, here's where there's a lot stuff to consider. Now I confess, I'm not an expert on all of these settings, The good news is that if I can't give you enough details, your PP person probably can, since these are the same setting for production orders :smile:

Adust Dates: Determines if and how the basic dates or the dependent requirements dates are adjusted during scheduling, and after scheduling. The short story is that you can change the basic order dates and/or change the dependent requirement dates (when you need parts/operations to start). There are the following possibilities:

- The basic dates are adjusted and the dependent requirements are scheduled for the start dates of the relevant operations.

- The basic dates are not adjusted and the dependent requirements are scheduled for the start dates of the relevant operations.

- The basic dates are adjusted and the dependent requirements are scheduled for the order basic start date.

- The basic dates are not adjusted and the dependent requirements are scheduled for the order basic start date.

Scheduling Type: This is what we talked about in the last post. You pick how things should be scheduled. Some of the most popular are forward or backward scheduling.

Start in the Past: You can enter in the maximum number of days you'll allow the order to start in the past. For example, you might say it can start in the past, but no more than 3 days. If you leave it blank, there are no maximums.

Automatic Scheduling: Exactly what it sounds like. The scheduling happens automatically upon release/save.

Automatic Log: The log is generated automatically after the scheduling takes place (manual or automatic)

Scheduling with Breaks: Will you take breaks/lunch into consideration when scheduling???

Shift Order: This gives you additional flexibility for partially confirmed operations and should the original dates be taken into account.

Latest Staging Date:Used for material staging, the indicator works like this (straight from SAP help):

- Components with a positive requirements quantity if the requirements date is the latest schedule date of the activity. If you do not set the indicator, the requirements date is the earliest scheduled date of the activity.

- Components with a negative requirements quantity if the requirements date is the latest finish date of the activity. you do not set the indicator, the requirements date is the earliest finish date of the activity.

Finally, the bottom of the screen has a bunch of things L1 - L6. Which are the percentage by which the safety margins before and after production are to be reduced in the order for reduction level X (1 to 6).

Now, based on your organization, it's likely that either you will use the same settings as production orders, or you may have to do some trial and error to find the best settings for your service group. I encourage you to start with the defaults, and do your unit testing and see how it behaves. Likely, you won't need to change a lot of the settings beyond the scheduling type.

If you're interested in great tips and tricks on SAP service management, variant configuration or production planning, check out my blog at: http://javeLLinSolutions.com/blog/

There is also a link to some SAP Easy Buttons 😃

Thanks for reading,

Mike

CTO - JaveLLin Solutions, LLC

- SAP Managed Tags:

- PLM (Product Lifecycle Management),

- SAP Business Process Management

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

-

"mm02"

1 -

A_PurchaseOrderItem additional fields

1 -

ABAP

1 -

ABAP Extensibility

1 -

ACCOSTRATE

1 -

ACDOCP

1 -

Adding your country in SPRO - Project Administration

1 -

Advance Return Management

1 -

AI and RPA in SAP Upgrades

1 -

Approval Workflows

1 -

ARM

1 -

ASN

1 -

Asset Management

1 -

Associations in CDS Views

1 -

auditlog

1 -

Authorization

1 -

Availability date

1 -

Azure Center for SAP Solutions

1 -

AzureSentinel

2 -

Bank

1 -

BAPI_SALESORDER_CREATEFROMDAT2

1 -

BRF+

1 -

BRFPLUS

1 -

Bundled Cloud Services

1 -

business participation

1 -

Business Processes

1 -

CAPM

1 -

Carbon

1 -

Cental Finance

1 -

CFIN

1 -

CFIN Document Splitting

1 -

Cloud ALM

1 -

Cloud Integration

1 -

condition contract management

1 -

Connection - The default connection string cannot be used.

1 -

Custom Table Creation

1 -

Customer Screen in Production Order

1 -

Data Quality Management

1 -

Date required

1 -

Decisions

1 -

desafios4hana

1 -

Developing with SAP Integration Suite

1 -

Direct Outbound Delivery

1 -

DMOVE2S4

1 -

EAM

1 -

EDI

2 -

EDI 850

1 -

EDI 856

1 -

edocument

1 -

EHS Product Structure

1 -

Emergency Access Management

1 -

Energy

1 -

EPC

1 -

Financial Operations

1 -

Find

1 -

FINSSKF

1 -

Fiori

1 -

Flexible Workflow

1 -

Gas

1 -

Gen AI enabled SAP Upgrades

1 -

General

1 -

generate_xlsx_file

1 -

Getting Started

1 -

HomogeneousDMO

1 -

IDOC

2 -

Integration

1 -

Learning Content

2 -

LogicApps

2 -

low touchproject

1 -

Maintenance

1 -

management

1 -

Material creation

1 -

Material Management

1 -

MD04

1 -

MD61

1 -

methodology

1 -

Microsoft

2 -

MicrosoftSentinel

2 -

Migration

1 -

MRP

1 -

MS Teams

2 -

MT940

1 -

Newcomer

1 -

Notifications

1 -

Oil

1 -

open connectors

1 -

Order Change Log

1 -

ORDERS

2 -

OSS Note 390635

1 -

outbound delivery

1 -

outsourcing

1 -

PCE

1 -

Permit to Work

1 -

PIR Consumption Mode

1 -

PIR's

1 -

PIRs

1 -

PIRs Consumption

1 -

PIRs Reduction

1 -

Plan Independent Requirement

1 -

Premium Plus

1 -

pricing

1 -

Primavera P6

1 -

Process Excellence

1 -

Process Management

1 -

Process Order Change Log

1 -

Process purchase requisitions

1 -

Product Information

1 -

Production Order Change Log

1 -

Purchase requisition

1 -

Purchasing Lead Time

1 -

Redwood for SAP Job execution Setup

1 -

RISE with SAP

1 -

RisewithSAP

1 -

Rizing

1 -

S4 Cost Center Planning

1 -

S4 HANA

1 -

S4HANA

3 -

Sales and Distribution

1 -

Sales Commission

1 -

sales order

1 -

SAP

2 -

SAP Best Practices

1 -

SAP Build

1 -

SAP Build apps

1 -

SAP Cloud ALM

1 -

SAP Data Quality Management

1 -

SAP Maintenance resource scheduling

2 -

SAP Note 390635

1 -

SAP S4HANA

2 -

SAP S4HANA Cloud private edition

1 -

SAP Upgrade Automation

1 -

SAP WCM

1 -

SAP Work Clearance Management

1 -

Schedule Agreement

1 -

SDM

1 -

security

2 -

Settlement Management

1 -

soar

2 -

SSIS

1 -

SU01

1 -

SUM2.0SP17

1 -

SUMDMO

1 -

Teams

2 -

User Administration

1 -

User Participation

1 -

Utilities

1 -

va01

1 -

vendor

1 -

vl01n

1 -

vl02n

1 -

WCM

1 -

X12 850

1 -

xlsx_file_abap

1 -

YTD|MTD|QTD in CDs views using Date Function

1

- « Previous

- Next »

- SAP Fiori for SAP S/4HANA - Composite Roles in launchpad content and layout tools in Enterprise Resource Planning Blogs by SAP

- Account Balance Validation in SAP S/4HANA Cloud, Public Edition in Enterprise Resource Planning Blogs by SAP

- Scheduling parameters usage & what is forward scheduling & backward scheduling in maintenance orders in Enterprise Resource Planning Q&A

- An introduction into Service Management in S/4HANA Cloud Private Edition in Enterprise Resource Planning Blogs by SAP

- Manage work center capacity for maintenance order in Enterprise Resource Planning Q&A

| User | Count |

|---|---|

| 5 | |

| 2 | |

| 2 | |

| 2 | |

| 2 | |

| 2 | |

| 2 | |

| 1 | |

| 1 |