- SAP Community

- Products and Technology

- Enterprise Resource Planning

- ERP Blogs by Members

- Quality Control of Geochemical Samples in Mining I...

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

1. Introduction

This Blog describes the Quality Control of Geochemical Samples in Mining Industry and the terminology related. Very often in the mining industry, there are various physical, chemical, acid and other tests that are to be conducted to assess the quality of the metal ores. Due to the volatile nature of the various materials such Iron Ore, Phosphorus Ore etc.,, their properties needs to be checked frequently. For example, percentage of moisture, compressive strength, density, Percentage of Oxides, porosity, Loss on Ignition, Metal % etc., change with the time.

2. Terminology Used in Quality Analysis (Mining Industry)

2.1. Point of Analysis

- Origin Analysis:

Quality results are checked at the Mining site

- Destination Analysis:

Quality results are checked at the Destination/Customer site

- Negotiation:

Quality results are sometimes decided by negotiating between Mining Company & Customer. (Depends on the Agreements between two parties)

2.2. Parties conducting the Analysis

- Client:

Quality results are checked by the Mining Company

- Independent:

Quality results are checked by the Independent Vendor (decided by both Mining Company & Customer)

- Umpire:

Quality results are checked by the Third Party

- Customer:

Quality results are checked by the Customer

2.3. Geographical Location/Testing Laboratory

- Location/Laboratory:

Analysis conducted at a particular geographical place or location. For example, Laboratory, Oman, New York etc.,

3. Mining Industry Requirement

As the quality parameter values vary frequently, many a times, the quality analysis is carried out is differentiated based on the Geographical location, Time & the party conducting the tests. Due to these reasons, many results are recorded for the same characteristic. In order to accommodate these requirements in SAP Quality Management module, the Origin of Results Data can be used. This concept avoids creating multiple characteristics for the same quality parameter that is to be checked. Moreover, in Mining Industry, the invoicing and billing depends on quality of the mining material. For example, for the Material Ore with less moisture percentage is invoiced with less cost when compared to the Material Ore with more moisture percentage. This can be addressed using the Origin of Results Data.

4. Significance of Origin of Results Data

The results origin entry defines the source of information. This can be assigned to the characteristic in the Inspection Plan or in the Results recording screen. As long as the inspection characteristic has the status "in process", results origin during results recording can be specified.

5. Configuration Required in SAP

Navigation Path: SPRO > Quality Management > Quality Inspection > Results Recording > Define Origins of Results Data

| Origin of Results Data | Short Text |

| Z1 | Origin - Client Analysis |

| Z2 | Origin - Independent Analysis |

| Z3 | Origin - Umpire Analysis |

| Z4 | Origin - Customer Analysis |

| Z5 | Destination - Client Analysis |

| Z6 | Destination - Independent Analysis |

| Z7 | Destination - Umpire Analysis |

| Z8 | Destination - Customer Analysis |

| Z9 | Negotiated Client and Customer Analysis |

| ZA | Oman Main Laboratory |

| ZB | Oman Supporting Laboratory |

| ZC | Oman External Laboratory |

5.1. Detailed Explanation of Configured values

- In the Origin of Results data configured, Z1 to Z8 are analysis values with reference to the Parties conducting the Test (Client/Independent/Umpire/Customer) and the Point of Analysis (Origin/Destination)

- Z9 refers to the negotiated value between Client and the Customer

- ZA to ZB are the values with reference to Geographical location (Oman Lab)

- In addition to the description of the results origin, data source for the inspection results also can be selected in the configuration

6. SAP Scenario

Below is the scenario demonstrated for usage of Origin of Results Data.

6.1. Master Data

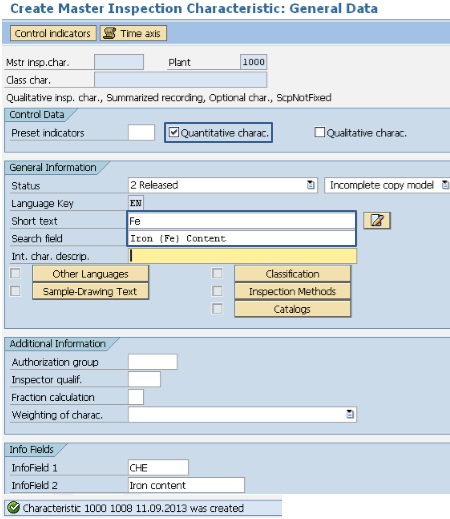

6.1.1. Master Inspection Characteristic

- Create Master Inspection Characteristic Master using Transaction code QS21

- Iron content (Fe) is considered in the below example with Quantitative characteristic

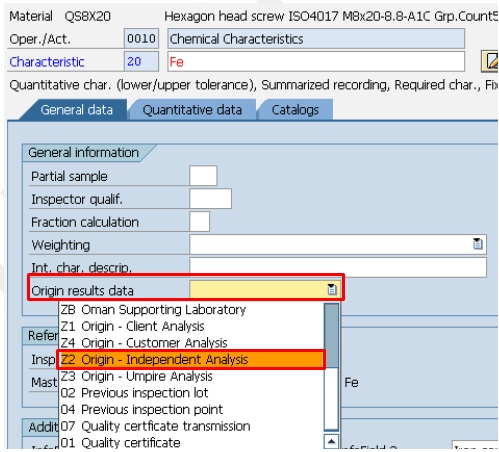

6.1.2. Inspection Plan – Result of Origin assignment

- Create Inspection Plan using Transaction code QP01.

- Assign Master Inspection characteristic for the Operation.

- Single Master Inspection characteristic (Fe) is assigned to assess the same characteristic at various ports or at different point of time etc.,

- Select Master Inspection characteristic and Click on General Data Details

- Assign Origin Results Data Z1- Origin - Client Analysis for the Characteristic as shown below.

- Similarly, assign Origin Results Data Z2 - Origin - Independent Analysis for the Characteristic 20 as shown below.

- After assigning the Origin results data for all the characteristics, save the inspection plan. Message will be displayed as below.

6.2. Transaction Steps

6.2.1. Inspection Lot creation

- Create Inspection Lot using Transaction QA01 (Inspection Type 01 is used in the below example).

- Enter Quantity details & assign Inspection Plan.

6.2.2. Results Recording

- Record the results for the characteristic using QA02/QE51N transaction

- In the Record Results: Characteristic Overview screen, we can observe that the result is recorded for the same characteristic with different Origin Results Data.

7. Benefits derived with Usage of Origin of Results Data

7.1. Invoicing

Depending on the agreement between the Mining Company and the Customer/Vendor, the appropriate result can be considered for the Invoicing (out of all the values recorded for the same characteristic).

7.2. Batch Update Functionality

Minor enhancement can be done to the standard batch update functionality while taking Usage decision for the inspection lot, in order to update the batch value with one of the results recorded based on pre-configured conditions.

- SAP Managed Tags:

- Chemicals,

- Mining,

- SAP ERP,

- PLM (Product Lifecycle Management),

- PLM Quality Management (QM)

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

-

"mm02"

1 -

A_PurchaseOrderItem additional fields

1 -

ABAP

1 -

ABAP Extensibility

1 -

ACCOSTRATE

1 -

ACDOCP

1 -

Adding your country in SPRO - Project Administration

1 -

Advance Return Management

1 -

AI and RPA in SAP Upgrades

1 -

Approval Workflows

1 -

ARM

1 -

ASN

1 -

Asset Management

1 -

Associations in CDS Views

1 -

auditlog

1 -

Authorization

1 -

Availability date

1 -

Azure Center for SAP Solutions

1 -

AzureSentinel

2 -

Bank

1 -

BAPI_SALESORDER_CREATEFROMDAT2

1 -

BRF+

1 -

BRFPLUS

1 -

Bundled Cloud Services

1 -

business participation

1 -

Business Processes

1 -

CAPM

1 -

Carbon

1 -

Cental Finance

1 -

CFIN

1 -

CFIN Document Splitting

1 -

Cloud ALM

1 -

Cloud Integration

1 -

condition contract management

1 -

Connection - The default connection string cannot be used.

1 -

Custom Table Creation

1 -

Customer Screen in Production Order

1 -

Data Quality Management

1 -

Date required

1 -

Decisions

1 -

desafios4hana

1 -

Developing with SAP Integration Suite

1 -

Direct Outbound Delivery

1 -

DMOVE2S4

1 -

EAM

1 -

EDI

2 -

EDI 850

1 -

EDI 856

1 -

edocument

1 -

EHS Product Structure

1 -

Emergency Access Management

1 -

Energy

1 -

EPC

1 -

Financial Operations

1 -

Find

1 -

FINSSKF

1 -

Fiori

1 -

Flexible Workflow

1 -

Gas

1 -

Gen AI enabled SAP Upgrades

1 -

General

1 -

generate_xlsx_file

1 -

Getting Started

1 -

HomogeneousDMO

1 -

IDOC

2 -

Integration

1 -

learning content

2 -

LogicApps

2 -

low touchproject

1 -

Maintenance

1 -

management

1 -

Material creation

1 -

Material Management

1 -

MD04

1 -

MD61

1 -

methodology

1 -

Microsoft

2 -

MicrosoftSentinel

2 -

Migration

1 -

MRP

1 -

MS Teams

2 -

MT940

1 -

Newcomer

1 -

Notifications

1 -

Oil

1 -

open connectors

1 -

Order Change Log

1 -

ORDERS

2 -

OSS Note 390635

1 -

outbound delivery

1 -

outsourcing

1 -

PCE

1 -

Permit to Work

1 -

PIR Consumption Mode

1 -

PIR's

1 -

PIRs

1 -

PIRs Consumption

1 -

PIRs Reduction

1 -

Plan Independent Requirement

1 -

Premium Plus

1 -

pricing

1 -

Primavera P6

1 -

Process Excellence

1 -

Process Management

1 -

Process Order Change Log

1 -

Process purchase requisitions

1 -

Product Information

1 -

Production Order Change Log

1 -

Purchase requisition

1 -

Purchasing Lead Time

1 -

Redwood for SAP Job execution Setup

1 -

RISE with SAP

1 -

RisewithSAP

1 -

Rizing

1 -

S4 Cost Center Planning

1 -

S4 HANA

1 -

S4HANA

3 -

Sales and Distribution

1 -

Sales Commission

1 -

sales order

1 -

SAP

2 -

SAP Best Practices

1 -

SAP Build

1 -

SAP Build apps

1 -

SAP Cloud ALM

1 -

SAP Data Quality Management

1 -

SAP Maintenance resource scheduling

2 -

SAP Note 390635

1 -

SAP S4HANA

2 -

SAP S4HANA Cloud private edition

1 -

SAP Upgrade Automation

1 -

SAP WCM

1 -

SAP Work Clearance Management

1 -

Schedule Agreement

1 -

SDM

1 -

security

2 -

Settlement Management

1 -

soar

2 -

SSIS

1 -

SU01

1 -

SUM2.0SP17

1 -

SUMDMO

1 -

Teams

2 -

User Administration

1 -

User Participation

1 -

Utilities

1 -

va01

1 -

vendor

1 -

vl01n

1 -

vl02n

1 -

WCM

1 -

X12 850

1 -

xlsx_file_abap

1 -

YTD|MTD|QTD in CDs views using Date Function

1

- « Previous

- Next »

- Airline community content available on SAP Analytics Cloud in Enterprise Resource Planning Blogs by SAP

- Prevent Receipt elements generation for BOM components with specific Products in Enterprise Resource Planning Blogs by Members

- SAP S/4HANA Extensibility Options For Clean Core Journey in Enterprise Resource Planning Blogs by SAP

- Physical sample on component from production order in Enterprise Resource Planning Q&A

- SAP Workflow Management and Loosely-coupled Architecture in Enterprise Resource Planning Blogs by SAP

| User | Count |

|---|---|

| 3 | |

| 2 | |

| 2 | |

| 2 | |

| 2 | |

| 2 | |

| 2 | |

| 2 | |

| 2 | |

| 1 |