- SAP Community

- Groups

- Industry Groups

- SAP for Utilities

- Blogs

- IT – OT Integration: designing future Operations a...

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

Since some time ago, and thanks to the irruption of new technologies such as HANA and mobility we are shifting the level of the Enterprise Asset Management platforms towards the creation of integrated systems which can assist effectively users providing predictions and forecasts in all relevant

processes of Operations and Maintenance.

From the Technology point of view, this transformation is an ongoing process with different levels of maturity both in systems and basic knowledge (experience). Its adoption, despite the value that clearly provides to the organizations, is also challenging as companies have different levels of maturity and data quality of their O&M systems and conservative approaches (including prototypes) are frequent.

Roadmap – Maturity level concept based on stages of maturity

As the above copied picture shows, we identify up to six potential IT – OT integration scenarios for Asset Management with different levels of maturity. Each of them has a clear value offering and can be adopted directly or progressively as following a roadmap. Goal of this approach is to offer companies different choices, for now and the future, enabling each to design its own IT – OT integration strategy for Asset Management according to their priorities.

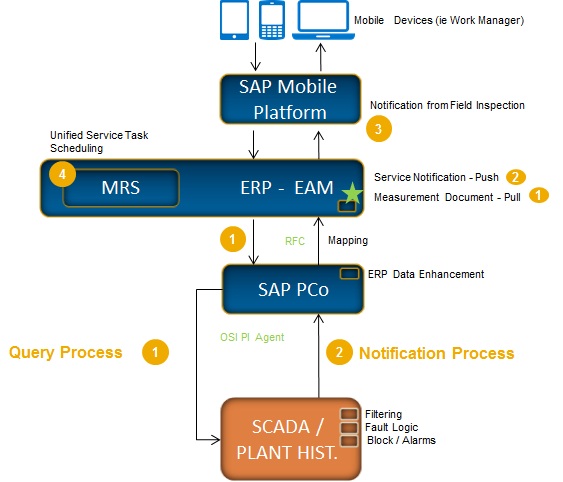

Scenario 1: Basic Condition Based Maintenance (simple rules) based in a Simple Integration with Plant Connectivity (SAP PCO).

This scenario provides a “quick win” to companies as enables the set up of automated Condition Based Maintenace scenarions by communicating data for sensors into the ERP through SAP PCO middleware. As described at the below copied graphic, these records enter into the ERP as EAM measurement documents influencing the parameters (measurement points) of equipments and functional locations already modelled in Maintenance Plans. By modelling this way, measurement documents with not expected parameters can trigger notifications or workorders.

Scenario 1: Basic Condition Based Maintenance (simple rules)

The set up of this scenario supports basic CBM rules (either in SAP PM or SAP Pco) such as “Temperature > 70°C” and provides the adventages of a lean deployement and low TCO. On the other side, this scenario does not provide intrinsic monitoring features nor enables the set up of sophisticated rules, such as trending.

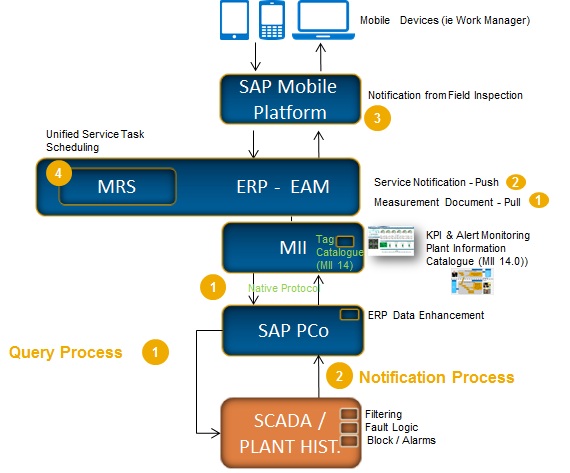

Scenario 2: Failure Alert Handling (Monitoring of Simple Rules) Through the Integration with Machine Integration and Information (SAP MII)

This scenario adds to the previous one a reliable, almost ready to set up platform to monitor signals (events) and take decisions (Event evaluation) such

as outages, Alert monitoring and KPI analysis. Mapping and integration with ERP is provided as well as a functionality named Plant Information Catalog to mapp with the Tags of the SCADA / Plant Historian systems. PCO system is part of MII application so the integration is secured.

Scenario 2: CBM using MII

MII can be deployed very quick based on a RDS pack (Rapid Deployement Solution).

Scenario 3: Complete Condition Based Maintenace (Complex Rules, Trends, correlation of Values) by Integrating with MII and Event Stream

Processor (SAP ESP)

The set up of Event Stream Processor is due to the fact that it supports continous monitoring data stream. With this application it can be modelled correlation, trending and pattern analysis with service notification creation into the ERP for processing.

Scenario 3: Complete Condition Based Maintenace

Scenarios 4 to 6: Set up a complete IT OT integration asset management platform by introducing HANA

By introducing HANA (natively integrated with ESP component) on the already described landscape it can be set up retrospective analytics for the historical data cummulated from the relevant equipments as well as perform patern detection and verification analysis. From the other hand data can also be used to predict and forecast maintenance scenarios.

Scenario 4 to 6: adavanced and predictive analytics supported by Real Time Data Platform

Benefits of this architecture is to achieve a comprehensive 360° maintenance scenario including monitoring tools. This is an area yet to explore completely so Co Innovation projects to define Predictive Maintenance scenarios are currently going on, and this is Innovation: the overall architecture enables not only to set up an instance where to perform advanced analytics processes, forecasting and retrospective but also to introduce new business processes in the business suite as, for example, near time production resource scheduling or basic economic dispatch for energy production.

Learn more about this subject and more by registering for the SAP Utilities Forum North America in Huntington Beach, California, September 15-17th

- SAP Managed Tags:

- Utilities

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

-

customer centricity

1 -

cx

1 -

Life at SAP

2 -

Master Data

1 -

newsletter

1 -

Product Updates

2 -

Roadmap

1 -

S4 HANA

1 -

S4 HANA On-Premise

1 -

Utilities

2 -

utilities event

1