- SAP Community

- Products and Technology

- Enterprise Resource Planning

- ERP Blogs by Members

- Equipment Availability - Concept & Issues

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

Equipment Availability - Concept & Issues

______________________________________________________________________________________

Author: Jogeswara Rao Kavala

The Objective:

In many industrial situations, performance analyses often lead to queries about the Equipment Availability.

This document mainly gives the concepts of the same and discusses about the calculations and issues in calculations.

The Availability & MTTR, MTBR

The Availability of an Equipment is known by different names such as

- Equipment Availability

- Operational Availability etc.

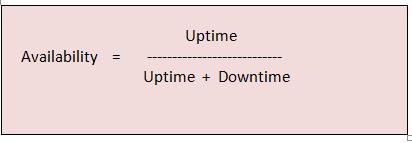

Common formula used for the Equipment Availability computation is

This is expressed in percentage and calculated using the following methods

___________________________________________________________________________

Method1

Where

A (Available Hrs) = Mission period in Hrs – Maintenance Hours

B (Breakdown Hours) = Downtime in jobs recorded through M2 Notifications

Mission Period in Hrs = 720, when you are querying the report for a period of 30 days

(30*24).

Maintenance Hours is Downtime in Jobs recorded through preventive jobs.

(usually through M3 Notifications)

_______________________________________________________________________________________

Method 2

where

MTBR = Mean Time Between Repairs (Hrs)

(Also known as Mean Time Between Failures - MTBF)

MTTR = Mean Time To Repair (Hrs)

___________________________________________________________________________

MTTR and MTBR

Example Data:

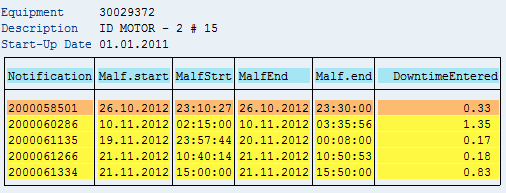

The above figure shows details of M2 Notifications (Breakdowns) in a month.

The Yellow lines indicate the details of 4 Breakdowns in the month.

The Brown line indicates the details of immediate previous breakdown.

MTTR = Sum of Downtimes (Hrs) / No. of Breakdowns

= (1.35 + 0.17 + 0.18 + 0.83) / 4

= 0.6325 Hrs

MTBR = Sum of Intervals between two

Breakdowns in sequence / No. of Breakdowns

(Here the Brown line details are

used to calculate the interval before the fist yellow-line.)

This comes to 153.45 Hrs.

Here the Availability = [ 153.45 / (153.45 + 0.6325) * 100 ] = 99.6 %

We know that MCJB and MCJC are the PMIS Tcodes to see the MTTR, MTBR values of an Equipment or a Functional Location respectively.

There will be no issues when availability figures are calculated through Z-Reports for equipments as individual objects.

But issues arise at Hierarchical cases like few explained below:

The ‘Crane’ situation:

End-users create Breakdown notifications simultaneously with several time overlaps on many equipments under a single Industrial Crane (F/L) during breakdown stoppage. They do not create any notification on Crane proper (F/L).

But expectations will be there that because of hierarchical representation in the system, database should be able to give the Availability figures at Crane Level.

Please see this article posted several months after the present one: Hierarchical Equipment Availability Calculations (on Functional Locations)

‘Functional Agencies’ Situation:

In the maintenance function of large manufacturing/process industries, maintenance agencies are sectionalised such as Mechanical, Electrical, Hydraulics, Instrumentation etc. Here these agencies record their Breakdowns / Preventive maintenance activities on their respective equipments independently.

The cases where proper structuring is not done with a focus to capture the availability figures on key assets, involving all the data entered by these agencies,the availability computations on top hierarchy equipments looks very difficult.

Please refer to this document for some situations like above: Hierarchical Equipment Availability Calculations (on Functional Locations)

-----@@@----

- SAP Managed Tags:

- PLM Enterprise Asset Management (EAM)/Plant Maintenance (PM)

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

-

"mm02"

1 -

A_PurchaseOrderItem additional fields

1 -

ABAP

1 -

ABAP Extensibility

1 -

ACCOSTRATE

1 -

ACDOCP

1 -

Adding your country in SPRO - Project Administration

1 -

Advance Return Management

1 -

AI and RPA in SAP Upgrades

1 -

Approval Workflows

1 -

ARM

1 -

ASN

1 -

Asset Management

1 -

Associations in CDS Views

1 -

auditlog

1 -

Authorization

1 -

Availability date

1 -

Azure Center for SAP Solutions

1 -

AzureSentinel

2 -

Bank

1 -

BAPI_SALESORDER_CREATEFROMDAT2

1 -

BRF+

1 -

BRFPLUS

1 -

Bundled Cloud Services

1 -

business participation

1 -

Business Processes

1 -

CAPM

1 -

Carbon

1 -

Cental Finance

1 -

CFIN

1 -

CFIN Document Splitting

1 -

Cloud ALM

1 -

Cloud Integration

1 -

condition contract management

1 -

Connection - The default connection string cannot be used.

1 -

Custom Table Creation

1 -

Customer Screen in Production Order

1 -

Data Quality Management

1 -

Date required

1 -

Decisions

1 -

desafios4hana

1 -

Developing with SAP Integration Suite

1 -

Direct Outbound Delivery

1 -

DMOVE2S4

1 -

EAM

1 -

EDI

2 -

EDI 850

1 -

EDI 856

1 -

EHS Product Structure

1 -

Emergency Access Management

1 -

Energy

1 -

EPC

1 -

Find

1 -

FINSSKF

1 -

Fiori

1 -

Flexible Workflow

1 -

Gas

1 -

Gen AI enabled SAP Upgrades

1 -

General

1 -

generate_xlsx_file

1 -

Getting Started

1 -

HomogeneousDMO

1 -

IDOC

2 -

integration

1 -

Learning Content

2 -

LogicApps

2 -

low touchproject

1 -

Maintenance

1 -

management

1 -

Material creation

1 -

Material Management

1 -

MD04

1 -

MD61

1 -

methodology

1 -

Microsoft

2 -

MicrosoftSentinel

2 -

Migration

1 -

MRP

1 -

MS Teams

2 -

MT940

1 -

Newcomer

1 -

Notifications

1 -

Oil

1 -

open connectors

1 -

Order Change Log

1 -

ORDERS

2 -

OSS Note 390635

1 -

outbound delivery

1 -

outsourcing

1 -

PCE

1 -

Permit to Work

1 -

PIR Consumption Mode

1 -

PIR's

1 -

PIRs

1 -

PIRs Consumption

1 -

PIRs Reduction

1 -

Plan Independent Requirement

1 -

Premium Plus

1 -

pricing

1 -

Primavera P6

1 -

Process Excellence

1 -

Process Management

1 -

Process Order Change Log

1 -

Process purchase requisitions

1 -

Product Information

1 -

Production Order Change Log

1 -

Purchase requisition

1 -

Purchasing Lead Time

1 -

Redwood for SAP Job execution Setup

1 -

RISE with SAP

1 -

RisewithSAP

1 -

Rizing

1 -

S4 Cost Center Planning

1 -

S4 HANA

1 -

S4HANA

3 -

Sales and Distribution

1 -

Sales Commission

1 -

sales order

1 -

SAP

2 -

SAP Best Practices

1 -

SAP Build

1 -

SAP Build apps

1 -

SAP Cloud ALM

1 -

SAP Data Quality Management

1 -

SAP Maintenance resource scheduling

2 -

SAP Note 390635

1 -

SAP S4HANA

2 -

SAP S4HANA Cloud private edition

1 -

SAP Upgrade Automation

1 -

SAP WCM

1 -

SAP Work Clearance Management

1 -

Schedule Agreement

1 -

SDM

1 -

security

2 -

Settlement Management

1 -

soar

2 -

SSIS

1 -

SU01

1 -

SUM2.0SP17

1 -

SUMDMO

1 -

Teams

2 -

User Administration

1 -

User Participation

1 -

Utilities

1 -

va01

1 -

vendor

1 -

vl01n

1 -

vl02n

1 -

WCM

1 -

X12 850

1 -

xlsx_file_abap

1 -

YTD|MTD|QTD in CDs views using Date Function

1

- « Previous

- Next »

- FAQ on Upgrading SAP S/4HANA Cloud Public Edition in Enterprise Resource Planning Blogs by SAP

- An introduction into Service Management in S/4HANA Cloud Private Edition in Enterprise Resource Planning Blogs by SAP

- Key Takeaways from Rise Into the Future Event: What You Need to Know in Enterprise Resource Planning Blogs by SAP

- SAP S/4HANA Cloud Private Edition | 2023 FPS01 Release – Part 2 in Enterprise Resource Planning Blogs by SAP

- SAP S/4HANA Cloud Private Edition | 2023 FPS01 Release – Part 1 in Enterprise Resource Planning Blogs by SAP

| User | Count |

|---|---|

| 2 | |

| 2 | |

| 1 | |

| 1 | |

| 1 | |

| 1 | |

| 1 | |

| 1 | |

| 1 |