- SAP Community

- Products and Technology

- Enterprise Resource Planning

- ERP Blogs by Members

- Missing Parts Check at the time of GR In SAP MM In...

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

HI Friends,

This document is about how missing parts check work in SAP MM Inventory Management.

Overview Of Missing Parts Check:

By using Missing parts check, the system checks at the time of goods receipt, other receipts or transfer posting of a material, whether it is a massing part or not. If that material is a missing part then system issues a warning message and also sends a mail to the responsible MRP Controller of the plant.

What is Missing Part:

A material is called as missing part when the available stock of that material is not sufficient to fulfill the existing reservations (requirements) of that material. So in order to fulfill those requirements you have to procure or produce that material. These requirements may be generated automatically (for ex: by means of Production order dependent requirements for raw materials which will create a reservation for raw materials) or Manually (For Ex: by means of reservation created manually in MB21 with movement type 201 goods issue to cost center).

Steps for activating Missing missing parts check:

1. Go to SPRO >> Materials Management >> Inventory Management >> Goods Receipt >> Set Missing Parts Check

Here activate the Missing parts check for your plant as shown below

You can also activate the same in inventory management plant parameters

2. Create Checking Rule

Here Create a checking Rule By clicking New Entries, and giving a code & Description (you can use any standard checking rule also... Ex: 03

3. Define Checking Rule

Here Define checking rule with the combination of availability checking group by clicking New entries.

Here select the stocks which needs to be considered as available stocks when checking a missing part against a required quantity.

Give checking period for missing parts. This checking period is a period in which system checks for a missing part after requirement date.

Here if you select the 'Check without RLT' then system will not consider the replenishment lead time.

4. Assign checking rule to the transaction code

Here you assign the checking rule to be used while executing particular transaction code

6. Assign Checking Rule to the movement type

Here assign checking rule to the movement type. This assignment is not mandatory. If you assign here, this checking rule takes precedence over checking rule of transaction code. If you not assign any rule, the system takes checking rule from transaction code.

Note: If you enter '**' here, the missing parts check will be deactivated exclusively for that movement type.

7. Assign availability check group to the material master

In MRP3 View of material master assign availability check group. and also assign MRP controller in MRP1 View of material Master. A mail will be sent to him about missing parts.

8. Define MRP Controller

Go to SPRO >> Materials Management >> Consumption-Based Planning >> Master Data >> Define MRP Controller

Here Dine MRP Controller in your plant and give User ID as shown below

Assign Central Missing Parts MRP Controller

Here assign a MRP Controller to your plant. This MRP Controller will be informed through mail about missing parts in case If you haven't maintained an MRP controller in the material master.

So now you are completed the Missing parts check back end settings.

Testing of Missing Parts Check at GR:

In order to test the missing parts check do the below steps.

1. Create a Goods issue Reservation for the material in MB21. For Ex: with Movement type 201 Goods issue to cost center.

2. Check the current stock status of the material in stock overview MMBE

3. Do Goods Receipt for the material For Ex: With movement type 501 (GR w/o PO) in TCode MIGO

After entering all the required data press check button. The system will show you warning message as shown below stating that material is missing part and MRP Controller will be informed.

Post the GR

4. Check business workplace of MRP Controller whether you received a mail about missing parts

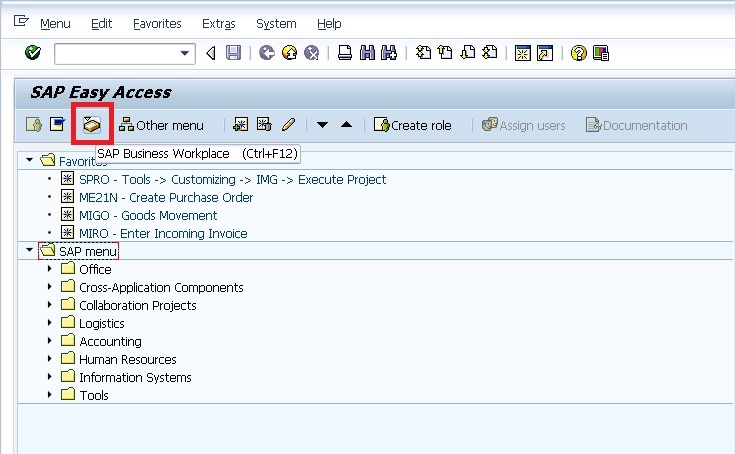

In easy access click on SAP business work place icon as show below

Here check your inbox whether you got any message about missing parts similar to shown below.

Note: The background or configuration settings behind this automatically sent mail are as explained below..

Go to SPRO >> Materials Management >> Inventory management >> Output Determination > Define OUtput types

Here check Message type 'MLFH' (Mail Message for missing Parts)

This message type is used to send the mail automatically to the MRP Controller USer ID. You dont required do any changes. BUt check whether this message type is assigned your message schema, in output determination this schema was assigned and check whethere a condition record exists for this message type.

Check sap Note 426648 - Missing part mail checklist for goods movements which is Relevant to this settings if you struck any where.

Difference between Summarized and Non summarized missing parts:

Non summarized missing parts:

If you not select summarize missing parts check box in plant parameters then, The MRP controller will receive a mail for each material including a maximum of five MRP elements requiring the material. For Ex: IF you are receiving 3 materials at a time and these are already missing parts then MRP controller will get 3 Individual mails for each material as show below.

Summarized missing parts

The MRP controller will receive a mail for each material document and plant. The mail contains the list of missing parts materials but no MRP elements. For Example: IF you are receving 3 materials at a time, in which two materials are missing parts then MRp Controller will get a single mail with the list of these two materials only as shown below.

-End

Thanks For reading and please share your feedback..

Regards

Satish

- SAP Managed Tags:

- SAP ERP,

- MM (Materials Management)

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

-

"mm02"

1 -

A_PurchaseOrderItem additional fields

1 -

ABAP

1 -

ABAP Extensibility

1 -

ACCOSTRATE

1 -

ACDOCP

1 -

Adding your country in SPRO - Project Administration

1 -

Advance Return Management

1 -

AI and RPA in SAP Upgrades

1 -

Approval Workflows

1 -

ARM

1 -

ASN

1 -

Asset Management

1 -

Associations in CDS Views

1 -

auditlog

1 -

Authorization

1 -

Availability date

1 -

Azure Center for SAP Solutions

1 -

AzureSentinel

2 -

Bank

1 -

BAPI_SALESORDER_CREATEFROMDAT2

1 -

BRF+

1 -

BRFPLUS

1 -

Bundled Cloud Services

1 -

business participation

1 -

Business Processes

1 -

CAPM

1 -

Carbon

1 -

Cental Finance

1 -

CFIN

1 -

CFIN Document Splitting

1 -

Cloud ALM

1 -

Cloud Integration

1 -

condition contract management

1 -

Connection - The default connection string cannot be used.

1 -

Custom Table Creation

1 -

Customer Screen in Production Order

1 -

Data Quality Management

1 -

Date required

1 -

Decisions

1 -

desafios4hana

1 -

Developing with SAP Integration Suite

1 -

Direct Outbound Delivery

1 -

DMOVE2S4

1 -

EAM

1 -

EDI

2 -

EDI 850

1 -

EDI 856

1 -

edocument

1 -

EHS Product Structure

1 -

Emergency Access Management

1 -

Energy

1 -

EPC

1 -

Financial Operations

1 -

Find

1 -

FINSSKF

1 -

Fiori

1 -

Flexible Workflow

1 -

Gas

1 -

Gen AI enabled SAP Upgrades

1 -

General

1 -

generate_xlsx_file

1 -

Getting Started

1 -

HomogeneousDMO

1 -

IDOC

2 -

Integration

1 -

Learning Content

2 -

LogicApps

2 -

low touchproject

1 -

Maintenance

1 -

management

1 -

Material creation

1 -

Material Management

1 -

MD04

1 -

MD61

1 -

methodology

1 -

Microsoft

2 -

MicrosoftSentinel

2 -

Migration

1 -

MRP

1 -

MS Teams

2 -

MT940

1 -

Newcomer

1 -

Notifications

1 -

Oil

1 -

open connectors

1 -

Order Change Log

1 -

ORDERS

2 -

OSS Note 390635

1 -

outbound delivery

1 -

outsourcing

1 -

PCE

1 -

Permit to Work

1 -

PIR Consumption Mode

1 -

PIR's

1 -

PIRs

1 -

PIRs Consumption

1 -

PIRs Reduction

1 -

Plan Independent Requirement

1 -

Premium Plus

1 -

pricing

1 -

Primavera P6

1 -

Process Excellence

1 -

Process Management

1 -

Process Order Change Log

1 -

Process purchase requisitions

1 -

Product Information

1 -

Production Order Change Log

1 -

Purchase requisition

1 -

Purchasing Lead Time

1 -

Redwood for SAP Job execution Setup

1 -

RISE with SAP

1 -

RisewithSAP

1 -

Rizing

1 -

S4 Cost Center Planning

1 -

S4 HANA

1 -

S4HANA

3 -

Sales and Distribution

1 -

Sales Commission

1 -

sales order

1 -

SAP

2 -

SAP Best Practices

1 -

SAP Build

1 -

SAP Build apps

1 -

SAP Cloud ALM

1 -

SAP Data Quality Management

1 -

SAP Maintenance resource scheduling

2 -

SAP Note 390635

1 -

SAP S4HANA

2 -

SAP S4HANA Cloud private edition

1 -

SAP Upgrade Automation

1 -

SAP WCM

1 -

SAP Work Clearance Management

1 -

Schedule Agreement

1 -

SDM

1 -

security

2 -

Settlement Management

1 -

soar

2 -

SSIS

1 -

SU01

1 -

SUM2.0SP17

1 -

SUMDMO

1 -

Teams

2 -

User Administration

1 -

User Participation

1 -

Utilities

1 -

va01

1 -

vendor

1 -

vl01n

1 -

vl02n

1 -

WCM

1 -

X12 850

1 -

xlsx_file_abap

1 -

YTD|MTD|QTD in CDs views using Date Function

1

- « Previous

- Next »

- Advance Return Management complete configuration(SAP ARM) in Enterprise Resource Planning Blogs by Members

- How to set up the Data Migration Cockpit in Enterprise Resource Planning Blogs by Members

- SAP S/4HANA Cloud, public edition, ABAP Environment Case 8: Material Shelf Life Management in Enterprise Resource Planning Blogs by SAP

- SAP S/4HANA Cloud ABAP开发案例之八:物料临期管理App in Enterprise Resource Planning Blogs by SAP

- Manage Supply Shortage and Excess Supply with MRP Material Coverage Apps in Enterprise Resource Planning Blogs by SAP

| User | Count |

|---|---|

| 6 | |

| 2 | |

| 2 | |

| 2 | |

| 2 | |

| 2 | |

| 1 | |

| 1 | |

| 1 |