- SAP Community

- Products and Technology

- Enterprise Resource Planning

- ERP Blogs by Members

- Cycle counting: Configuration, Process flow and Im...

Enterprise Resource Planning Blogs by Members

Gain new perspectives and knowledge about enterprise resource planning in blog posts from community members. Share your own comments and ERP insights today!

Turn on suggestions

Auto-suggest helps you quickly narrow down your search results by suggesting possible matches as you type.

Showing results for

Product and Topic Expert

Options

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

05-13-2013

4:38 AM

This is brief overview for implementing cycle counting process in the SAP inventory management (IM) module.

What is cycle counting?

Cycle counting is a method of physical inventory whereby inventory is counted at regular intervals within a fiscal year. Physical inventory may be required by financial accounting rules or tax regulations. Cycle counting process is less disruptive to operations. This process can be integrated in daily operations, for e.g., count 200 materials at beginning of shift (20 people counts 10 materials each).

Cycle Counting allows you to count fast-moving items more frequently than slow-moving items.

Cycle counting process is fairly easy to implement. This process increases accuracy of inventory.

Cycle counting is a method of physical inventory whereby inventory is counted at regular intervals within a fiscal year. Physical inventory may be required by financial accounting rules or tax regulations. Cycle counting process is less disruptive to operations. This process can be integrated in daily operations, for e.g., count 200 materials at beginning of shift (20 people counts 10 materials each).

Cycle Counting allows you to count fast-moving items more frequently than slow-moving items.

Cycle counting process is fairly easy to implement. This process increases accuracy of inventory.

Configuration

Cycle count indicator

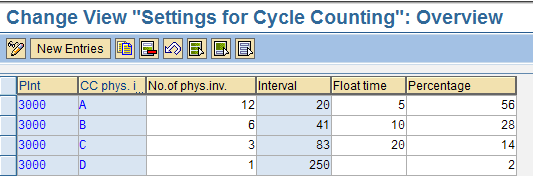

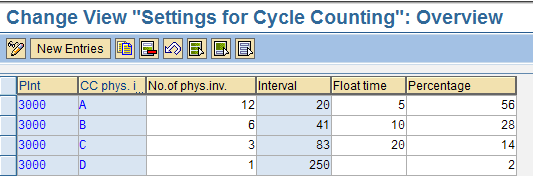

Follow this configuration path: IMG - Materials Management - Inventory management and Physical inventory - Physical inventory - Cycle counting (Tcode: OMCO)

Configure following parameters

1. Define the allowed cycle counting indicators in the plant.

2. Make the required settings for each indicator.

No. of phys. inventories per fiscal year for cycle counting: Specifies how often during the fiscal year a physical inventory is to be carried out for a material subject to cycle counting. This parameter will convert count interval in work days.

Interval: The count interval is determined automatically on the basis of the number of physical inventories specified for the fiscal year.

Float time: Indicates the number of workdays by which the planned count date may vary from the current date.

For the plant 3000, the float time is five days. A physical inventory has been planned for a material belonging to category C for June, 1. On expiration of the float time (after June, 6), the physical inventory has not yet been carried out. Irrespective of the category, the material is parked for the next cycle counting run.

Percentage: Specifies the percentage allocation of the materials to the individual cycle counting categories. The percentage value is used for automatic assignment of the cycle counting indicator during ABC analysis.

Settings for physical inventory

No. of phys. inventories per fiscal year for cycle counting: Specifies how often during the fiscal year a physical inventory is to be carried out for a material subject to cycle counting. This parameter will convert count interval in work days.

Interval: The count interval is determined automatically on the basis of the number of physical inventories specified for the fiscal year.

Float time: Indicates the number of workdays by which the planned count date may vary from the current date.

For the plant 3000, the float time is five days. A physical inventory has been planned for a material belonging to category C for June, 1. On expiration of the float time (after June, 6), the physical inventory has not yet been carried out. Irrespective of the category, the material is parked for the next cycle counting run.

Percentage: Specifies the percentage allocation of the materials to the individual cycle counting categories. The percentage value is used for automatic assignment of the cycle counting indicator during ABC analysis.

Settings for physical inventory

This is more generic physical inventory settings, but it may impact cycle counting process

- Change documents are activated for physical inventory document.

- The book inventory balance is adjusted in the physical inventory.

- Serial number management is setup. In the above example, last five digits of serial numbers will be printed on physical inventory document.

Reason for movement

Follow this configuration path: IMG - Materials Management - Inventory management and Physical inventory - Movement type - Reason for movement (tcode: OMBS)

As per your business requirement configure reason code for movement type 701, 702

Master data

1. Cycle counter indicator set for the material’s plant data 1 tab. (Tcode: MM02)

1. Cycle counter indicator set for the material’s plant data 1 tab. (Tcode: MM02)

This indicator is set if the material is to be cycle counted. It can also determine how the count is taken and how often. It groups the materials together into various cycle counting categories. Usually, these categories correspond to the ABC analysis of the materials. ABC analysis can be done via report MIBC (Program RMCBIN00).

2. Cycle counting indicator is fixed:

This means that the cycle counting indicator cannot be changed for cycle counting by an ABC analysis.

Execution / Process flow chart

This means that the cycle counting indicator cannot be changed for cycle counting by an ABC analysis.

Execution / Process flow chart

Here is flow chart for cycle counting process

Assuming cycle count indicator is set on materials, first step in cycle count process is to create cycle counting documents.

MICN - Create Physical Inventory Documents for Cycle Counting

This report is to create batch input session’s physical inventory documents for the cycle counting physical inventory procedure.

Selection

Restrict selection based on Material number, storage location, Material group etc.

In addition to unrestricted-use stock, you can include stock in quality inspection and blocked stock in the selection.

By specifying a threshold value, you can define that only stocks above or up to a particular level are included.

Selection

Restrict selection based on Material number, storage location, Material group etc.

In addition to unrestricted-use stock, you can include stock in quality inspection and blocked stock in the selection.

By specifying a threshold value, you can define that only stocks above or up to a particular level are included.

Physical inventory number

You can setup batch job with different variants for generating cycle count sheets in MICN. You can use TVARV table to customize physical inventory number and/or physical inventory reference. For example: you want to have different reference numbers for each storage locations for ease of reporting. You can use above reference number in setting up next job for auto printing physical inventory document via MI21.

Posting block

Indicates that no goods movements involving the materials listed in the physical inventory document can be posted for the duration of a physical inventory count.

The indicator is set for the affected stocks in each case (storage location stock, batch stock, or special stock), for all associated stock types and is not cancelled until the count results are posted.

The blocking indicator can be setup in one of two ways:

• Directly upon entry of the physical inventory document (if the count is to take place immediately).

• Shortly before the count (if the count is to place later).

Indicates that no goods movements involving the materials listed in the physical inventory document can be posted for the duration of a physical inventory count.

The indicator is set for the affected stocks in each case (storage location stock, batch stock, or special stock), for all associated stock types and is not cancelled until the count results are posted.

The blocking indicator can be setup in one of two ways:

• Directly upon entry of the physical inventory document (if the count is to take place immediately).

• Shortly before the count (if the count is to place later).

Freeze book inventory

It specifies the book inventory balances of those items in a physical inventory document that have not yet been counted and are frozen. This indicator has the effect that the current book inventory balance is recorded in the physical inventory document. The system compares the counted stock with the frozen book inventory balance to determine any inventory differences. If the count results are not entered immediately after the stock has been counted, it is useful to set this indicator so that any goods movements which may take place in the meantime will not change the book inventory balance relevant to the physical inventory.

For example: Business process is to count inventory before shift begins, and then after few hours inventory administrator enters counts. In this case do not set ‘Posting block’, as production will need to perform goods issue. In this case set ‘Freeze book inventory’, so inventory count will be measured against inventory at the time when physical inventory documents were created.

It specifies the book inventory balances of those items in a physical inventory document that have not yet been counted and are frozen. This indicator has the effect that the current book inventory balance is recorded in the physical inventory document. The system compares the counted stock with the frozen book inventory balance to determine any inventory differences. If the count results are not entered immediately after the stock has been counted, it is useful to set this indicator so that any goods movements which may take place in the meantime will not change the book inventory balance relevant to the physical inventory.

For example: Business process is to count inventory before shift begins, and then after few hours inventory administrator enters counts. In this case do not set ‘Posting block’, as production will need to perform goods issue. In this case set ‘Freeze book inventory’, so inventory count will be measured against inventory at the time when physical inventory documents were created.

Output of MICN

Output will have all materials for which physical inventory documents can be created.

It then lists the stock management units for which a physical inventory is already active, but has not been completed within the predefined float time and therefore must be completed urgently. These stock management units are not included when the batch input session is created because active physical inventory documents already exist.

In addition, the list contains all materials for which cycle counting is required within the planned interval (specified interval for the planned count date). If a physical inventory had already been due prior to the planned interval, the planned count date would be highlighted.

The remaining steps are self-explanatory. Inventory reference number can be used for the rest of the transaction to complete cycle counting process.

MI21 – Print Physical inventory document

Here you can specify:

Output will have all materials for which physical inventory documents can be created.

It then lists the stock management units for which a physical inventory is already active, but has not been completed within the predefined float time and therefore must be completed urgently. These stock management units are not included when the batch input session is created because active physical inventory documents already exist.

In addition, the list contains all materials for which cycle counting is required within the planned interval (specified interval for the planned count date). If a physical inventory had already been due prior to the planned interval, the planned count date would be highlighted.

The remaining steps are self-explanatory. Inventory reference number can be used for the rest of the transaction to complete cycle counting process.

MI21 – Print Physical inventory document

Here you can specify:

• Grouping criteria e.g. Group by bin number

• Sorting criteria for serial numbers

MI24 – Physical inventory list

This transaction can be used as working transaction for inventory administrators. User can use inventory reference number to group cycle counting document.

In this transaction user can enter count, monitor progress, run analysis and post counts.

MI24 – Physical inventory list

This transaction can be used as working transaction for inventory administrators. User can use inventory reference number to group cycle counting document.

In this transaction user can enter count, monitor progress, run analysis and post counts.

Integration

When the inventory differences are posted, the total stock is automatically adjusted to the counted quantity on the document. When the document is posted, the difference will correspond to either a goods receipt of goods issue. This affects following areas:

• Material planning for production or sale orders

• Stock value on balance sheet

Tips

When the inventory differences are posted, the total stock is automatically adjusted to the counted quantity on the document. When the document is posted, the difference will correspond to either a goods receipt of goods issue. This affects following areas:

• Material planning for production or sale orders

• Stock value on balance sheet

Tips

1. If there is any historical record for last cycle date, during cutover update field DLINL in MARD table to continue cycle counting process

2. Refer to SAP note 518418 - FAQ: Cycle Counting

3. Physical inventory can be counted for special stocks as well e.g. MIW1 – Consignment at Customer, MIO1 – Material provided to vendor

Source: help.sap.com

Also posted on: http://www.sapience-solutions.com/sapeince-blog.php

PDF for above document: http://www.sapience-solutions.com/resources/May_2013_Cycle_counting.pdf

I welcome your comments/suggestions/insights.

Thanks,

- SAP Managed Tags:

- SAP ERP,

- MM (Materials Management)

14 Comments

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

Labels in this area

-

"mm02"

1 -

A_PurchaseOrderItem additional fields

1 -

ABAP

1 -

ABAP Extensibility

1 -

ACCOSTRATE

1 -

ACDOCP

1 -

Adding your country in SPRO - Project Administration

1 -

Advance Return Management

1 -

AI and RPA in SAP Upgrades

1 -

Approval Workflows

1 -

ARM

1 -

ASN

1 -

Asset Management

1 -

Associations in CDS Views

1 -

auditlog

1 -

Authorization

1 -

Availability date

1 -

Azure Center for SAP Solutions

1 -

AzureSentinel

2 -

Bank

1 -

BAPI_SALESORDER_CREATEFROMDAT2

1 -

BRF+

1 -

BRFPLUS

1 -

Bundled Cloud Services

1 -

business participation

1 -

Business Processes

1 -

CAPM

1 -

Carbon

1 -

Cental Finance

1 -

CFIN

1 -

CFIN Document Splitting

1 -

Cloud ALM

1 -

Cloud Integration

1 -

condition contract management

1 -

Connection - The default connection string cannot be used.

1 -

Custom Table Creation

1 -

Customer Screen in Production Order

1 -

Data Quality Management

1 -

Date required

1 -

Decisions

1 -

desafios4hana

1 -

Developing with SAP Integration Suite

1 -

Direct Outbound Delivery

1 -

DMOVE2S4

1 -

EAM

1 -

EDI

2 -

EDI 850

1 -

EDI 856

1 -

edocument

1 -

EHS Product Structure

1 -

Emergency Access Management

1 -

Energy

1 -

EPC

1 -

Financial Operations

1 -

Find

1 -

FINSSKF

1 -

Fiori

1 -

Flexible Workflow

1 -

Gas

1 -

Gen AI enabled SAP Upgrades

1 -

General

1 -

generate_xlsx_file

1 -

Getting Started

1 -

HomogeneousDMO

1 -

IDOC

2 -

Integration

1 -

learning content

2 -

LogicApps

2 -

low touchproject

1 -

Maintenance

1 -

management

1 -

Material creation

1 -

Material Management

1 -

MD04

1 -

MD61

1 -

methodology

1 -

Microsoft

2 -

MicrosoftSentinel

2 -

Migration

1 -

MRP

1 -

MS Teams

2 -

MT940

1 -

Newcomer

1 -

Notifications

1 -

Oil

1 -

open connectors

1 -

Order Change Log

1 -

ORDERS

2 -

OSS Note 390635

1 -

outbound delivery

1 -

outsourcing

1 -

PCE

1 -

Permit to Work

1 -

PIR Consumption Mode

1 -

PIR's

1 -

PIRs

1 -

PIRs Consumption

1 -

PIRs Reduction

1 -

Plan Independent Requirement

1 -

Premium Plus

1 -

pricing

1 -

Primavera P6

1 -

Process Excellence

1 -

Process Management

1 -

Process Order Change Log

1 -

Process purchase requisitions

1 -

Product Information

1 -

Production Order Change Log

1 -

Purchase requisition

1 -

Purchasing Lead Time

1 -

Redwood for SAP Job execution Setup

1 -

RISE with SAP

1 -

RisewithSAP

1 -

Rizing

1 -

S4 Cost Center Planning

1 -

S4 HANA

1 -

S4HANA

3 -

Sales and Distribution

1 -

Sales Commission

1 -

sales order

1 -

SAP

2 -

SAP Best Practices

1 -

SAP Build

1 -

SAP Build apps

1 -

SAP Cloud ALM

1 -

SAP Data Quality Management

1 -

SAP Maintenance resource scheduling

2 -

SAP Note 390635

1 -

SAP S4HANA

2 -

SAP S4HANA Cloud private edition

1 -

SAP Upgrade Automation

1 -

SAP WCM

1 -

SAP Work Clearance Management

1 -

Schedule Agreement

1 -

SDM

1 -

security

2 -

Settlement Management

1 -

soar

2 -

SSIS

1 -

SU01

1 -

SUM2.0SP17

1 -

SUMDMO

1 -

Teams

2 -

User Administration

1 -

User Participation

1 -

Utilities

1 -

va01

1 -

vendor

1 -

vl01n

1 -

vl02n

1 -

WCM

1 -

X12 850

1 -

xlsx_file_abap

1 -

YTD|MTD|QTD in CDs views using Date Function

1

- « Previous

- Next »

Related Content

- Quick Start guide for PLM system integration 3.0 Implementation/Installation in Enterprise Resource Planning Blogs by SAP

- FAQ on Upgrading SAP S/4HANA Cloud Public Edition in Enterprise Resource Planning Blogs by SAP

- FAQ: S/4HANA Cloud, public edition - Sales in Enterprise Resource Planning Blogs by SAP

- Downloading Your Business Configuration Adaptations in SAP Central Business Configuration in Enterprise Resource Planning Blogs by SAP

- How to Set Up Approval Workflows for Supplier Down Payment Requests in Enterprise Resource Planning Blogs by SAP

Top kudoed authors

| User | Count |

|---|---|

| 3 | |

| 2 | |

| 2 | |

| 2 | |

| 2 | |

| 2 | |

| 2 | |

| 2 | |

| 1 |