- SAP Community

- Products and Technology

- Enterprise Resource Planning

- ERP Blogs by Members

- COLLECTIVE ORDER OR DIRECT PRODUCTION - A scenario...

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

Direct Production or Collective order – Scenario Overview

(Author: N. Mohan Raj )

Introduction:

This White paper explains briefly on the scenario of direct production or collective order concept. Basically, collective order is the technical term used for the Direct Production scenario.

Main objective of the document is to explain the basic concept of collective order with Business examples as well as sap Process flow. Best attempt has been made to explain key settings, advantages, Disadvantages & Limitations of collective order. I would also update versions based on feedback and comments of SDN experts and consultants on this topic accordingly in future.

Collective order or direct Production can be carried out for Discrete Manufacturing or PP-PI. However this document limits to Discrete Manufacturing only.

Applies to: ECC 6.0, Sap R/3 4.6

Need for Direct production or Collective order:

If subassemblies are produced directly for superior orders within a production process, without physically entering the warehouse, then it is useful to have direct production via collective orders.

Example:

1. Joining of Left door & Right door assembly in a car

2. Fitting of Front & rear wheel assembly in cycle or Bike

Direct Production:

Direct production is the special type of production where components are directly produced for the higher-level assembly, without Stocked @ warehouse as normal and no goods receipt or goods issue postings are made for components that are produced directly.

The system flags a direct production segment for the components to be produced directly in the MRP list and the stock/requirements list. When the planned order for the finished product is converted into a production order, the system also converts all planned orders for lower-level components to be produced directly into production orders.

The system adapts planned orders for direct production to changes in date and quantity in the higher-level assembly, even if they are firmed, so that the collective order remains consistent.

Collective order:

Collective order is a network where planned orders or production orders are linked to each another over several production levels. Each order in the collective order has its own order number. The components for which separate production orders are created in the collective order are called directly produced components.

Business scenario:

Let us understand Business scenarios where collective order or Direct Production scenario is used before briefing the sap process flow.

In Our professional life, we used to get below items from our Company or in any events

a) Ball pen or Mug or Bottle embedded with Company name

b) Wrist watch or wall clock with company logo & name

c) Wallet or Bag or Sun glass embedded with Company or sponsor

If the manufacturer uses exclusive components for producing above finished product where he wants to control production with linkage of header & child orders with no intermediate stock transfer to warehouse, then Collective order process will be helpful.

Above examples are just for explanation purpose of collective order in a better way but it is not limited .You can use Collective order concept in general where components has to be issued only to Superior orders instead of warehouse as unrestricted stock .

Sap Process Flow of Collective order:

- A. Configuration:

- A.1 Order Type Setting:

IMG path:

Production --> Shop Floor control --> Master data --> order --> Define order Types

Tcode: OPJH

If this indicator is set , then it means there are automatic goods movements between the production orders in a collective order. When the goods movement is posted,costs are credited from the subordinate order& costs are debited to the superior order.

, then it means there are automatic goods movements between the production orders in a collective order. When the goods movement is posted,costs are credited from the subordinate order& costs are debited to the superior order.

A.2. Special Procurement Key:

IMG path:

Production --> Material requirement planning --> Master data --> Define special procurement type

Case study:

Let us take manufacturing of Ball Pen, a simple example for the scenario of collective order processing.

Product structure:

1 Ball Pen (Finished Product)

1.1 Pen casing ( Halb)

1.1.1 Refill for Pen casing (ROH)

1.2 Pen Cap (Halb)

1.2.1 Slug for Pen cap (ROH)

Master Data:

1. Multi level BOM for Ball Pen & Routing

TCODE: CS12

2. Material Master:

2.1 Header Material MRP views:

TCODE: MM02

2.2 Child Material MRP views:

TCODE: MM03

Production planning & Control Cycle :

Collective order can be created by below 3 methods

1. Directly Production order with Header Material using Tcode : CO01

2. Create Planned order ( Tcode : MD11) for Header & Convert into Production order (Tcode :CO40)

3. PIR -------> MRP -----> Planned order to Production order.

Let us illustrate by Method 3 with Full cycle of Material Planning & Shop Floor Execution.

Material Planning:

i. creation of Planned Independent requirement (MD61 😞

ii. MRP RUN (MD02) :

I. iii Stock Requirement List (MD04) :

A. Stock requirement list for Header Material & child material :

Planned order for Header material & child material are created for the balance required qty (17)

*** You can notice Description “Direct Production “& Dep req for Header material .

I. iv .Order Report:

If we execute order report, we can see linkage of planned order as a network in below screen shot.

I. v. Planned order :

Here is the advantage of collective order concept. Subordinate planned orders are linked to superior header order which can be seen in assignment tab of below screen shot of child planned orders.

TCODE: MD13

I. vi. Conversion of planned order to production order :

Refer stock requirement list below once planned order of header material is converted

Shop Floor Execution:

Real Benefits of collective order concept starts here. Mark *** highlights its advantage

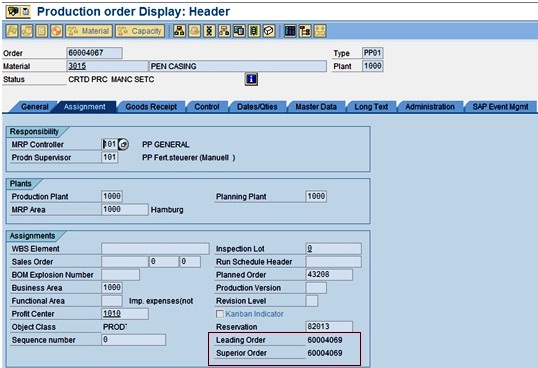

I. Creation of collective production order (CO03) :

When we click read collective order button, system will display collective order network @ created stage as below.

Note : Collective orders represent different levels of the production process together as an integrated whole network. Each level represents a prod order.

*** Refer assignment linkage of subordinate order to Leading /superior order below

I. ii. Scheduling of collective production order (CO02) :

***If we schedule header superior order, it automatically schedule total network of collective order.

iii. Releasing of collective production order (CO02) :

*** Releasing the superior order results in release of all child orders in network. Header order receives “RLNE” status – Release in Network.

I. iv. Changing collective production order (CO02) :

*** We can change header order Quantity or Scheduling Date or both which will gets drilldown to entire network below. Read PP master data function for header order is allowed.

Note: Below case, we have changed order qty from 17 to 15 which got drilled down.

I. v.Confirmation of collective production order (CO15 or CO11n) :

Confirmation of child order @ order level or operation level will result in direct Good issue to header order. Stock of subordinate order will not be available in warehouse .Instead; child component is directly produced for Header order.

Note that leading order will get below status when there is confirmation or goods movement in network.

1.1. CFCO Confirmation in collective order

1.2. GMCO Goods movements in collective order

*** Check warehouse stock for the direct components which is nil. TCODE: MB52

*** Check Material document for the direct components which shows GI for order (261) --TCODE: MB51

vi.Final confirmation of leading order :

I. vii. GR of collective production order (MB31) :

Refer FInal material document & Stock overview

This concludes the complete cycle of direct production via collective order

Limitations:

We have limitation to create collective order if components are belongs to below set

- Co Product or By product

- Alternative item of strategy 2 or usage probability 0

- Either Discontinued or Follow up or Intra Material

Moreover, Collective order cannot be created Via SAP APO.

Exception settings:

- If you want to restrict direct production for a particular BOM, then you enter this in the respective BOM item. This entry overwrites the entry in the material master. or

- You can use the indicator "No direct production" in the explosion key to switch off the direct production for individual BOMs.

TCODE: CS02

Conclusion:

In general , Direct production is aimed at doing Major sap business functions such as Creation ,Release ,scheduling ,costing for Finished product ,assembly & components within a BOM structure jointly or collectively.

Even though direct production or collective order has its unique benefits, it has a negative impact of Material flow & stock inventory indirectly. Collective order will not consider below points

- · Plant warehouse stock of direct components.

- · Anonymous Dependent requirements are not considered.

i would be happy to include feedback and improvement points from SDN PP experts in subsequent Versions for the benefit of Members .

Reference:

1. 1. http://help.sap.com/erp2005_ehp_06/helpdata/en/b1/c0500c439a11d189410000e829fbbd/content.htm?framese...

2. 2. http://scn.sap.com/message/7241069

1.

I.

I.

GR

- SAP Managed Tags:

- SAP ERP,

- MAN Production Planning (PP)

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

-

"mm02"

1 -

A_PurchaseOrderItem additional fields

1 -

ABAP

1 -

ABAP Extensibility

1 -

ACCOSTRATE

1 -

ACDOCP

1 -

Adding your country in SPRO - Project Administration

1 -

Advance Return Management

1 -

AI and RPA in SAP Upgrades

1 -

Approval Workflows

1 -

ARM

1 -

ASN

1 -

Asset Management

1 -

Associations in CDS Views

1 -

auditlog

1 -

Authorization

1 -

Availability date

1 -

Azure Center for SAP Solutions

1 -

AzureSentinel

2 -

Bank

1 -

BAPI_SALESORDER_CREATEFROMDAT2

1 -

BRF+

1 -

BRFPLUS

1 -

Bundled Cloud Services

1 -

business participation

1 -

Business Processes

1 -

CAPM

1 -

Carbon

1 -

Cental Finance

1 -

CFIN

1 -

CFIN Document Splitting

1 -

Cloud ALM

1 -

Cloud Integration

1 -

condition contract management

1 -

Connection - The default connection string cannot be used.

1 -

Custom Table Creation

1 -

Customer Screen in Production Order

1 -

Data Quality Management

1 -

Date required

1 -

Decisions

1 -

desafios4hana

1 -

Developing with SAP Integration Suite

1 -

Direct Outbound Delivery

1 -

DMOVE2S4

1 -

EAM

1 -

EDI

2 -

EDI 850

1 -

EDI 856

1 -

EHS Product Structure

1 -

Emergency Access Management

1 -

Energy

1 -

EPC

1 -

Find

1 -

FINSSKF

1 -

Fiori

1 -

Flexible Workflow

1 -

Gas

1 -

Gen AI enabled SAP Upgrades

1 -

General

1 -

generate_xlsx_file

1 -

Getting Started

1 -

HomogeneousDMO

1 -

IDOC

2 -

Integration

1 -

Learning Content

2 -

LogicApps

2 -

low touchproject

1 -

Maintenance

1 -

management

1 -

Material creation

1 -

Material Management

1 -

MD04

1 -

MD61

1 -

methodology

1 -

Microsoft

2 -

MicrosoftSentinel

2 -

Migration

1 -

MRP

1 -

MS Teams

2 -

MT940

1 -

Newcomer

1 -

Notifications

1 -

Oil

1 -

open connectors

1 -

Order Change Log

1 -

ORDERS

2 -

OSS Note 390635

1 -

outbound delivery

1 -

outsourcing

1 -

PCE

1 -

Permit to Work

1 -

PIR Consumption Mode

1 -

PIR's

1 -

PIRs

1 -

PIRs Consumption

1 -

PIRs Reduction

1 -

Plan Independent Requirement

1 -

Premium Plus

1 -

pricing

1 -

Primavera P6

1 -

Process Excellence

1 -

Process Management

1 -

Process Order Change Log

1 -

Process purchase requisitions

1 -

Product Information

1 -

Production Order Change Log

1 -

Purchase requisition

1 -

Purchasing Lead Time

1 -

Redwood for SAP Job execution Setup

1 -

RISE with SAP

1 -

RisewithSAP

1 -

Rizing

1 -

S4 Cost Center Planning

1 -

S4 HANA

1 -

S4HANA

3 -

Sales and Distribution

1 -

Sales Commission

1 -

sales order

1 -

SAP

2 -

SAP Best Practices

1 -

SAP Build

1 -

SAP Build apps

1 -

SAP Cloud ALM

1 -

SAP Data Quality Management

1 -

SAP Maintenance resource scheduling

2 -

SAP Note 390635

1 -

SAP S4HANA

2 -

SAP S4HANA Cloud private edition

1 -

SAP Upgrade Automation

1 -

SAP WCM

1 -

SAP Work Clearance Management

1 -

Schedule Agreement

1 -

SDM

1 -

security

2 -

Settlement Management

1 -

soar

2 -

SSIS

1 -

SU01

1 -

SUM2.0SP17

1 -

SUMDMO

1 -

Teams

2 -

User Administration

1 -

User Participation

1 -

Utilities

1 -

va01

1 -

vendor

1 -

vl01n

1 -

vl02n

1 -

WCM

1 -

X12 850

1 -

xlsx_file_abap

1 -

YTD|MTD|QTD in CDs views using Date Function

1

- « Previous

- Next »

- The Role of SAP Business AI in the Chemical Industry. Overview in Enterprise Resource Planning Blogs by SAP

- Quick Start guide for PLM system integration 3.0 Implementation/Installation in Enterprise Resource Planning Blogs by SAP

- How to Create Outbound Delivery With order reference in SAP VL01N in Enterprise Resource Planning Blogs by Members

- Creation of Outbound Delivery using VL01N in SAP in Enterprise Resource Planning Q&A

- Advanced variant configuration in Enterprise Resource Planning Q&A

| User | Count |

|---|---|

| 2 | |

| 2 | |

| 2 | |

| 2 | |

| 2 | |

| 1 | |

| 1 | |

| 1 | |

| 1 | |

| 1 |