- SAP Community

- Products and Technology

- Enterprise Resource Planning

- ERP Blogs by Members

- WM+SD, pick & pack szenario

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

Szenario

WM picking for outbound delivery with delivery bound HUs

Background

One straight forward picking process in WM together with SD is to use internal units to collect all the picked goods.

As second step, repacking (consolidation) from internal units to shippable (external) units is required because internal units never leave warehouse towards customer.

As an optimization, the pick & pack process allows the picker to have shippable units (cartons, labels/printer) "on board" to generate fully packed and shippable units after picking. No repacking is required, goods issue can be posted after picking because picking & packing is done in one step

Customizing

Allows the assignemt of pick-HUs to transfer orders before confirmation

Master Data

A packaging material is required (created by MM01) for HU creation

Example process

Simple VL01NO without reference

Some WM relevant plant + storage location combination

Create TO for delivery by LT03

Assign one or many pick-HUs to transfer order (header). Here the packaging material is required.

The number generation & the behaviour of this step is mainly controlled by SM30 view V_T319

You may also use RF transactions for WM mostly named LM* to do this assignment

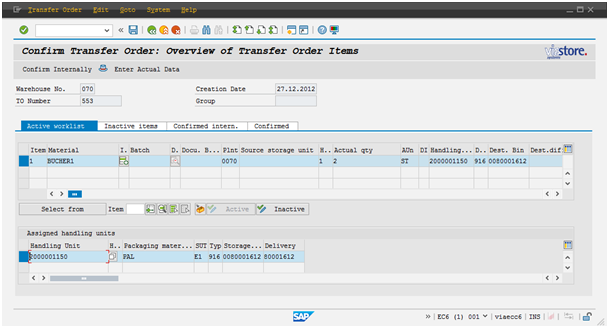

Confirm TO by LT12 (or by LM*), now a destination HU can be provided

After confirming the TO you'll get (for free 😉

- Picked delivery item

- Packed delivery item with qty from TO confirmation

- HU# created and item qty packed

Also a new item for HU could be created e.g.

- to print it on delivery note

- to get some money for it (out of FI)

The three major steps are

- assigning a list of potentional pick-HUs TO

- providing HUs at TO confirmation

- TO confirmation leads to a implicit packing of delivery item in given HU during TO confirmation

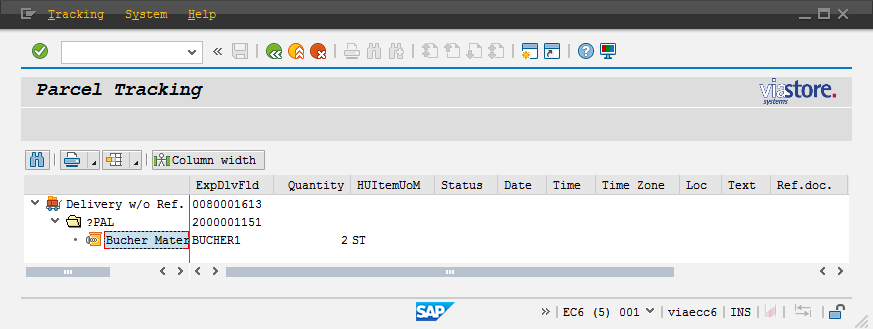

Thus LTHU-EXIDV will get VEKP-EXIDV if HU is selected at TO confirmation. As VEKP-EXIDV is the SSCC field (e.g. for parcel tracking), you may influnce the HU# generation at the LH01 step to get your SSCC number filled correct.

You also may influence the ABAP code (e.g. with implicit enhancement/BAdI implemenentation in SD) to repack a delivery item and update e.g. VEKP-EXIDV2 during that process.

Options

Parcel tracking

Could be done on HU level by transaction VTRK if SAP express shipping cockpit is enabled to update status per HU & carrier

SU/HU management

You can have SU management on source storage type and/or HU management on storage location level, but it's not required.

- SAP Managed Tags:

- SAP ERP,

- LE (Logistics Execution)

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

-

"mm02"

1 -

A_PurchaseOrderItem additional fields

1 -

ABAP

1 -

ABAP Extensibility

1 -

ACCOSTRATE

1 -

ACDOCP

1 -

Adding your country in SPRO - Project Administration

1 -

Advance Return Management

1 -

AI and RPA in SAP Upgrades

1 -

Approval Workflows

1 -

ARM

1 -

ASN

1 -

Asset Management

1 -

Associations in CDS Views

1 -

auditlog

1 -

Authorization

1 -

Availability date

1 -

Azure Center for SAP Solutions

1 -

AzureSentinel

2 -

Bank

1 -

BAPI_SALESORDER_CREATEFROMDAT2

1 -

BRF+

1 -

BRFPLUS

1 -

Bundled Cloud Services

1 -

business participation

1 -

Business Processes

1 -

CAPM

1 -

Carbon

1 -

Cental Finance

1 -

CFIN

1 -

CFIN Document Splitting

1 -

Cloud ALM

1 -

Cloud Integration

1 -

condition contract management

1 -

Connection - The default connection string cannot be used.

1 -

Custom Table Creation

1 -

Customer Screen in Production Order

1 -

Data Quality Management

1 -

Date required

1 -

Decisions

1 -

desafios4hana

1 -

Developing with SAP Integration Suite

1 -

Direct Outbound Delivery

1 -

DMOVE2S4

1 -

EAM

1 -

EDI

2 -

EDI 850

1 -

EDI 856

1 -

edocument

1 -

EHS Product Structure

1 -

Emergency Access Management

1 -

Energy

1 -

EPC

1 -

Financial Operations

1 -

Find

1 -

FINSSKF

1 -

Fiori

1 -

Flexible Workflow

1 -

Gas

1 -

Gen AI enabled SAP Upgrades

1 -

General

1 -

generate_xlsx_file

1 -

Getting Started

1 -

HomogeneousDMO

1 -

IDOC

2 -

Integration

1 -

learning content

2 -

LogicApps

2 -

low touchproject

1 -

Maintenance

1 -

management

1 -

Material creation

1 -

Material Management

1 -

MD04

1 -

MD61

1 -

methodology

1 -

Microsoft

2 -

MicrosoftSentinel

2 -

Migration

1 -

MRP

1 -

MS Teams

2 -

MT940

1 -

Newcomer

1 -

Notifications

1 -

Oil

1 -

open connectors

1 -

Order Change Log

1 -

ORDERS

2 -

OSS Note 390635

1 -

outbound delivery

1 -

outsourcing

1 -

PCE

1 -

Permit to Work

1 -

PIR Consumption Mode

1 -

PIR's

1 -

PIRs

1 -

PIRs Consumption

1 -

PIRs Reduction

1 -

Plan Independent Requirement

1 -

Premium Plus

1 -

pricing

1 -

Primavera P6

1 -

Process Excellence

1 -

Process Management

1 -

Process Order Change Log

1 -

Process purchase requisitions

1 -

Product Information

1 -

Production Order Change Log

1 -

Purchase requisition

1 -

Purchasing Lead Time

1 -

Redwood for SAP Job execution Setup

1 -

RISE with SAP

1 -

RisewithSAP

1 -

Rizing

1 -

S4 Cost Center Planning

1 -

S4 HANA

1 -

S4HANA

3 -

Sales and Distribution

1 -

Sales Commission

1 -

sales order

1 -

SAP

2 -

SAP Best Practices

1 -

SAP Build

1 -

SAP Build apps

1 -

SAP Cloud ALM

1 -

SAP Data Quality Management

1 -

SAP Maintenance resource scheduling

2 -

SAP Note 390635

1 -

SAP S4HANA

2 -

SAP S4HANA Cloud private edition

1 -

SAP Upgrade Automation

1 -

SAP WCM

1 -

SAP Work Clearance Management

1 -

Schedule Agreement

1 -

SDM

1 -

security

2 -

Settlement Management

1 -

soar

2 -

SSIS

1 -

SU01

1 -

SUM2.0SP17

1 -

SUMDMO

1 -

Teams

2 -

User Administration

1 -

User Participation

1 -

Utilities

1 -

va01

1 -

vendor

1 -

vl01n

1 -

vl02n

1 -

WCM

1 -

X12 850

1 -

xlsx_file_abap

1 -

YTD|MTD|QTD in CDs views using Date Function

1

- « Previous

- Next »

- Quick Start guide for PLM system integration 3.0 Implementation/Installation in Enterprise Resource Planning Blogs by SAP

- PICK&PACK DELIVERY LOCK in Enterprise Resource Planning Q&A

- SAP S/4HANA Cloud Private Edition | 2023 FPS01 Release – Part 1 in Enterprise Resource Planning Blogs by SAP

- Discrete Industries in SAP S/4HANA Cloud Public Edition 2402 in Enterprise Resource Planning Blogs by SAP

- Field inventory management (FIM) in the Medical Device Industry – Trunk Stock fulfillment to a medical sales representative in S4 HANA in Enterprise Resource Planning Blogs by Members

| User | Count |

|---|---|

| 2 | |

| 2 | |

| 2 | |

| 2 | |

| 2 | |

| 2 | |

| 2 | |

| 2 | |

| 1 | |

| 1 |