- SAP Community

- Products and Technology

- Enterprise Resource Planning

- ERP Blogs by Members

- SAP VC Material Variants : Creation,Usage in Sales...

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

Material Variants

Do you want to wait for customer order to plan and start production for the fastest selling and in demand configuration of your product ?

In many industries when we deal with Configurable material, many of times we come across a configuration which is asked every now and then by many customer.

Also business don’t want to wait for customer to enter order and then start its production , instead there is a need to have something similar to Make to Stock for this configuration to bring lead time down and maintain some stock of this fast moving configuration.

To address all of these and many other requirements, there is a standard option available in SAP to create “Material Variant”.

This document will be useful for beginners in VC area to understand the concept of Material Variant and how it can be setup using standard SAP. Also we will discuss how when you configure a material in sales order (VA01) or Configuration Simulation CU50, you can check whether a material variant already exists that has the same characteristic values and it will manually or automatically replace the configurable material in sales order. You can display existing material variants on the characteristic value assignment screen. However, the configurable material is not automatically replaced by the variant.

By definition from SAP Help,

Material Variants (1)

A material variant is a material that can be kept in stock and that arises from an individual configuration of a configurable product.

The material master record of a material variant is linked to the configurable material and configured using the characteristics of the configurable material. This variant of the configurable material can then be manufactured and kept in stock.

- You have a Configurable Product “BIKE” which has 3 attribute on which it can be configured, which become Characteristics of this configurable material.

These characteristics will have possible values associated

· COLOUR

o Red

o Blue

o Black

o Green

o Golden

o Silver

o Orange

o Purple

o Yellow

o Dark Red

· ENGINE TYPE

o 200 CC

o 400 CC

o 600 CC

o 800 CC

o 1000 CC

o 1200 CC

o 1400 CC

o 1500 CC

o 1600 CC

o 1800 CC

· EXHAUST

o S- EXHAUST 1

o S- EXHAUST 2

o S- EXHAUST 3

o S- EXHAUST 4

o S- EXHAUST 5

o S- EXHAUST 6

o S- EXHAUST 7

o S- EXHAUST 8

o S- EXHAUST 9

o S- EXHAUST 10

You created configurable material with all Basic settings required for “Variant Configuration”

(3)

(3)Below are the steps to create a Material Variant”, Create a new material, BIKE - BLACK - 1000

Transaction: MM01

(3)

(3)Select views

(3)

(3)Complete the material creation process by filling out necessary details and mandatory fields.

To manufacture the material variant in-house, you must maintain the variant at plant level, so that BOMs, routings, and so on can be determined. Cross-plant variants can be used in Purchasing, but are not supported in Sales.

To set up the material variant specific to a plant, in MRP 3 View, in field “Configurable Material ( MARC-STDPD) “ in put the configurable material number.

Press enter; you will get a message to “Configure the material.

(3)

(3)Press to configure this variant, you will get a pop-up

(3)

(3)Come out of the screen using,complete the process of creation of material following all required view and mandatory fields.

In the basic data, you can link the material variant to a configurable material. This configuration applies to all plants.

Now the Material Variant is created, and need to be linked with BOM and Routing of Configurable Material.

Transaction: CS40

(3)

(3)Press enter

(3)

(3)Save the assignment., Assign Routing

Transaction: CA02

(3)

(3)Open a routing of configurable material

(3)

(3)Use the material assignment option, Enter Group counter, Material and plant

(3)

(3)Save the routing.

Now the material Variant is ready to be used.

If the strategy group associated is relevant for “Make to stock: production, you can plan the independent requirement, have MRP run, generate plan order, convert it to production order and confirm to generate stock of this material variants.

Make to Stock Production for Variants (1)

Variants can be planned on the finished product level using any make-to-stock strategy, such as Planning with Final Assembly (40) or Net Requirements Planning (10)

Make to Order Production for Variants(1)

Variants can be planned on the finished product level using any make-to-order strategy, such as Planning w/o Final Assembly (50) or Planning with a Planning Material (60)

Replacement of Configurable material with material Variant in Sales order.

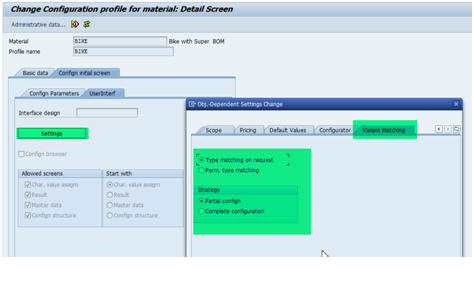

You can define the settings for variant matching in the configuration profile of a configurable material and on the characteristic value assignment screen.

- In the configuration profile, choose Settings, and on the characteristic value assignment screen choose View --Settings.

(3)

(3)

Prerequisites (1)

You define the settings for variant matching in Customizing for Sales and Distribution, where you maintain item categories.

§ Configuration of Sales and Distribution -> Sales -> Sales Document -> Sales Document Item -> Define Item Categories.

(3)

(3)

- Activate variant matching for an item category, by put a tick as shown above

- Define Material variant action to decide how the system reacts if it finds a material variant:

- The system automatically replaces the configurable material with the material variant.

- You see a message telling you that a material variant with the same configuration exists.

If the material variant is not available, you can:

- Receive an automatic message with a list of the material variant stock situation. You can then decide whether to replace the material variant.

- Decide that you do not want to replace the variant.

Create Sales order

Transaction VA01:

(3)

(3)

Input configurable material as required material

(3)

(3)

- Configure the configurable material in the sales order.

- On the value assignment screen, you can check whether material variants match the configuration of the material

(3)

(3)Material Variant matching the values will listed on lower part of screen.

(3)

(3)

(3)

(3)

(3)

(3)

- Once you have configured the material, leave the configuration editor.

- Depending on the settings in Customizing, either the material is replaced by the material variant immediately, or you see a message telling you that a suitable material variant has been found.

Save the sales order.

Individual or collective requirements can be generated for the material variant. Pricing also applies to the material variant, unless you define the configurable material as the pricing material for the material variant.

Relevant SAP Notes:

References:

(1) Some part of text copied from SAP help

(2) Link mention is a document by Philip Cluster on SAP SDN

(3) All screen copied are from SAP IDES

(z) courtesy : https://www.motorcyclelegalfoundation.com/types-of-motorcycles/

JSSJMDJSSS

- SAP Managed Tags:

- PLM Variant Configuration

- « Previous

-

- 1

- 2

- Next »

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

-

"mm02"

1 -

A_PurchaseOrderItem additional fields

1 -

ABAP

1 -

ABAP Extensibility

1 -

ACCOSTRATE

1 -

ACDOCP

1 -

Adding your country in SPRO - Project Administration

1 -

Advance Return Management

1 -

AI and RPA in SAP Upgrades

1 -

Approval Workflows

1 -

Ariba

1 -

ARM

1 -

ASN

1 -

Asset Management

1 -

Associations in CDS Views

1 -

auditlog

1 -

Authorization

1 -

Availability date

1 -

Azure Center for SAP Solutions

1 -

AzureSentinel

2 -

Bank

1 -

BAPI_SALESORDER_CREATEFROMDAT2

1 -

BRF+

1 -

BRFPLUS

1 -

Bundled Cloud Services

1 -

business participation

1 -

Business Processes

1 -

CAPM

1 -

Carbon

1 -

Cental Finance

1 -

CFIN

1 -

CFIN Document Splitting

1 -

Cloud ALM

1 -

Cloud Integration

1 -

condition contract management

1 -

Connection - The default connection string cannot be used.

1 -

Custom Table Creation

1 -

Customer Screen in Production Order

1 -

Data Quality Management

1 -

Date required

1 -

Decisions

1 -

desafios4hana

1 -

Developing with SAP Integration Suite

1 -

Direct Outbound Delivery

1 -

DMOVE2S4

1 -

EAM

1 -

EDI

3 -

EDI 850

1 -

EDI 856

1 -

edocument

1 -

EHS Product Structure

1 -

Emergency Access Management

1 -

Energy

1 -

EPC

1 -

Financial Operations

1 -

Find

1 -

FINSSKF

1 -

Fiori

1 -

Flexible Workflow

1 -

Gas

1 -

Gen AI enabled SAP Upgrades

1 -

General

1 -

generate_xlsx_file

1 -

Getting Started

1 -

HomogeneousDMO

1 -

IDOC

2 -

Integration

1 -

Learning Content

2 -

LogicApps

2 -

low touchproject

1 -

Maintenance

1 -

management

1 -

Material creation

1 -

Material Management

1 -

MD04

1 -

MD61

1 -

methodology

1 -

Microsoft

2 -

MicrosoftSentinel

2 -

Migration

1 -

mm purchasing

1 -

MRP

1 -

MS Teams

2 -

MT940

1 -

Newcomer

1 -

Notifications

1 -

Oil

1 -

open connectors

1 -

Order Change Log

1 -

ORDERS

2 -

OSS Note 390635

1 -

outbound delivery

1 -

outsourcing

1 -

PCE

1 -

Permit to Work

1 -

PIR Consumption Mode

1 -

PIR's

1 -

PIRs

1 -

PIRs Consumption

1 -

PIRs Reduction

1 -

Plan Independent Requirement

1 -

Premium Plus

1 -

pricing

1 -

Primavera P6

1 -

Process Excellence

1 -

Process Management

1 -

Process Order Change Log

1 -

Process purchase requisitions

1 -

Product Information

1 -

Production Order Change Log

1 -

purchase order

1 -

Purchase requisition

1 -

Purchasing Lead Time

1 -

Redwood for SAP Job execution Setup

1 -

RISE with SAP

1 -

RisewithSAP

1 -

Rizing

1 -

S4 Cost Center Planning

1 -

S4 HANA

1 -

S4HANA

3 -

Sales and Distribution

1 -

Sales Commission

1 -

sales order

1 -

SAP

2 -

SAP Best Practices

1 -

SAP Build

1 -

SAP Build apps

1 -

SAP Cloud ALM

1 -

SAP Data Quality Management

1 -

SAP Maintenance resource scheduling

2 -

SAP Note 390635

1 -

SAP S4HANA

2 -

SAP S4HANA Cloud private edition

1 -

SAP Upgrade Automation

1 -

SAP WCM

1 -

SAP Work Clearance Management

1 -

Schedule Agreement

1 -

SDM

1 -

security

2 -

Settlement Management

1 -

soar

2 -

Sourcing and Procurement

1 -

SSIS

1 -

SU01

1 -

SUM2.0SP17

1 -

SUMDMO

1 -

Teams

2 -

User Administration

1 -

User Participation

1 -

Utilities

1 -

va01

1 -

vendor

1 -

vl01n

1 -

vl02n

1 -

WCM

1 -

X12 850

1 -

xlsx_file_abap

1 -

YTD|MTD|QTD in CDs views using Date Function

1

- « Previous

- Next »

- SAP S/4HANA Cloud, Private Edition, and SAP S/4HANA | 2022 FPS01 Release – Part 1 in Enterprise Resource Planning Blogs by SAP

- Finance in SAP S/4HANA Cloud, Public Edition 2302 in Enterprise Resource Planning Blogs by SAP

- Replacement SD and FI configuration in Enterprise Resource Planning Q&A

- SAP VC Useful Documents in Enterprise Resource Planning Blogs by Members

- Variant Matching Function module in Enterprise Resource Planning Q&A

| User | Count |

|---|---|

| 5 | |

| 2 | |

| 2 | |

| 2 | |

| 2 | |

| 2 | |

| 2 | |

| 1 | |

| 1 | |

| 1 |