- SAP Community

- Products and Technology

- Spend Management

- Spend Management Blogs by Members

- Sequel 2 taking Direct Material procurement to the...

- Subscribe to RSS Feed

- Mark as New

- Mark as Read

- Bookmark

- Subscribe

- Printer Friendly Page

- Report Inappropriate Content

Recap

It’s been a while now that we have had a pause on the sequels for the SAP SRM 7.0 Ehp2 series of Innovations carved into blogs that you can relate to

This one is specifically the one that catches my attention around Direct Materials procurement with SAP SRM, as it has been a pain area for me / many in the projects that we have executed with challenging clients

If you have read my blog on Plan Driven Procurement with Plant Maintenance with SAP SRM 7.0, you would have got the breadth of the complexity of getting the process working as desired for the customer end to end.

With innovations with the SAP SRM 7.0 Ehp2, such complexities are ought to be addressed more product driven than actually going ahead and developing it.

1.0 Topic Overview

Direct Material Procurement Innovations with SAP SRM EhP2

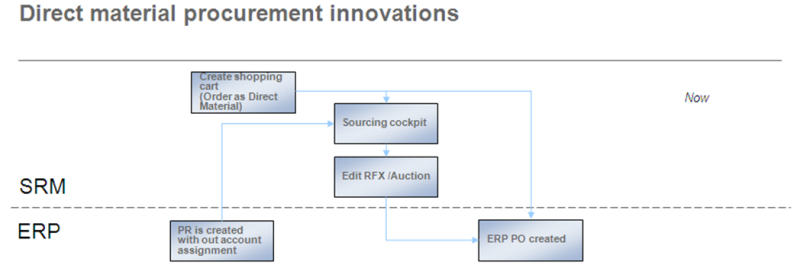

What’s coming: Direct Material procurement has been enabled for the Classic Scenario. In the Classic Scenario Purchase orders will be created in the ERP/ECC backend system

- Use of direct materials would create backend documents in the following scenarios:

- Ordering a shopping cart

- Carrying out sourcing for the shopping cart

- Carrying out sourcing for a purchase requisition transferred from the backend SAP ERP system

In a previous project, we had the issue of not being able to close the loop of the Purchase requisition when we create a PO to fulfill the request of a PR that has been treated from the SRM side, the design in the old way was that the system automatically treats the request as an Extended Classic scenario, we had to work our way using BADI’s to help close the loop b/w PR->SOCO->Sourcing->PO.

This very clearly resonates with the customer business challenges that exist with the process that we talked about in the above paragraph

- Direct materials scenarios limited to the extended classic deployment.

- This forced organizations to deploy extended classic for direct materials even when they want to deploy classic scenario

2.0 How did we do it before the EhP2? – A consultants approach

Used BADI, guess we have a great way out

BADI Name: BBP_PO_Inbound_BADI

Method: BBP_MAP_BEFORE_BAPI

Why did we use this?

This BADI is used to create a back-end Purchase Order from a BBP SRM EC Purchase Order, further the method BBP_MAP_BEFORE_BAPI is called before calling the PO create BAPI BBP_PO_CREATE1. We call this BADI to:

- Change the status from K to I generated by RFC default K coming in from SRM cannot be changed in ECC, this is done to overcome the Extended Classic PO to be changeable in ECC in ME22N, if this is not done the PO goes into ECC as a BBP Purchase Order and cannot be changed

The process in the old approach looked like this

The new process with the Innovation would look like this

Before the innovation, we had to tweak the process with some more BADI’s to help achieve what the Innovation kicks-in, so I am all excited as an SAP Procurement consultant to help reduce the development time for future projects for Direct Material Procurement with SAP SRM 7.0.

3.0 What business value does the Innovation bring in?

3.1 Flexibility with respect to deployment options.

Now you won’t have any constraints, if your process is heavily ECC or SRM driven, from both platforms, you would achieve what you need

3.2 Classic Deployment enabled for all categories of procurement including direct materials.

Direct Material procurement or in the traditional language as we call it BOM procurement constitutes to 60-70% of the spend, now you can source manage and honor those ECC sent requisitions and have a very tight closed loop process

Summary

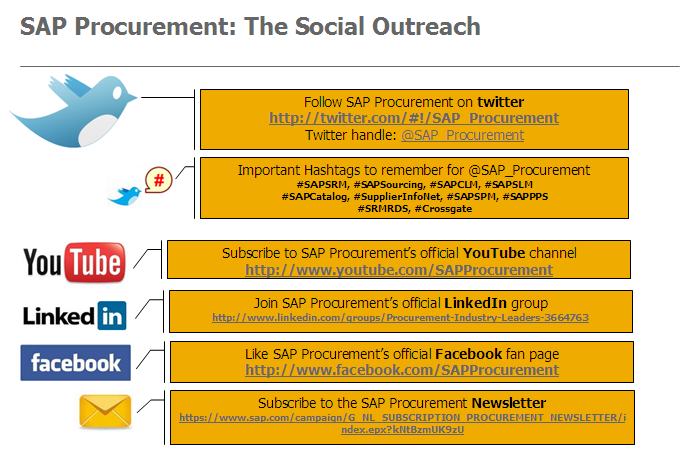

- Thanks for tuning into these sequels, am sure that with SAP SRM 7.0 EhP2, you will have more power in your hands as an SAP Procurement consultant to help deliver those go-to customer implementations. In our next blog, we will discuss more about the RFx creation from shopping cart before approval (Quick quotes) and some more innovations from the Streamlined sourcing processes Innovation bundle…so stay tuned. Before you head-out, please be aware about the various outreach channels for SAP Procurement

4.0 How do I achieve it?

- Activate Switch: SRM_702_DIRECT_MATERIAL

5.0) SAP Procurement social_media outreach channels

Hope to see you sign-up and follow our via all our Social Media Outreach channels

6.0) SAP Procurement handles & Hash-tags to follow

Happy Reading....

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in.

- Navigating the Risks of Sourcing Outside Your eSourcing Platform in Spend Management Blogs by SAP

- SAP Ariba Integration scenarios with SAP S/4HANA Public Cloud system in Spend Management Blogs by SAP

- The Procurement Monthly - March 2024 in Spend Management Blogs by SAP

- Getting Started as a New Supplier on SAP Business Network in Spend Management Blogs by SAP

- SAP Ariba Sourcing - Event Management API: Filter Sourcing Events by Date in Spend Management Blogs by SAP